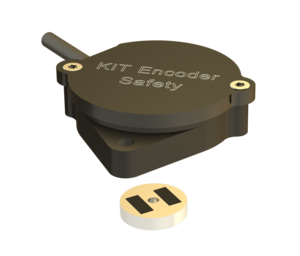

Absolute rotary sensor KIT TBN/S4 TWK

The TBN/S4 model is a new generation of bearingless rotary sensors that provides functional safety according to IEC 61508: SIL2 and ISO 13849: PLd in a cost-effective design. The flat housing with cable outlet offers a CANopen or CANopen Safety interface. Versions of the board without cover are available on request.

The position magnet is mechanically connected to the application, i.e. mounted on an application shaft or other moving part. The TBN case is placed in front of the magnet.

The wear-free device can be easily integrated into existing applications with limited installation space for safe position and velocity measurement..

Product category: rotary sensor

Incremental or Absolute: Absolute

Version: 55 mm

Mechanical connection: Mounting through Ø 5.5 through holes

Case material: aluminum 3.2315

Stainless steel 1.4404

plastic

PCB without cover on request

Resolution: 4096 steps/revolution 12 bit

8192 steps/revolution 13 bits

16,384 steps/revolution 14 bits

32,768 steps/revolution 15 bits

65536 steps/revolution 16 bits

Code type: Binary

Measuring range in revolutions: 1 for single revolution

2 to 32768 for multi-turn (2^n steps)

Profile: C3: CANopen standard version (DS406, 4.1.0)

S4: CANopen Safety certification (DS406, 4.1.0)

Electrical connection: 1 x cable with open strands

1 x cable with M12-A plug, 5-pin

1 x PCB Connector (Case Material = B)

2 x open fiber cable

2 x cable with plug/socket M12-A, 5-pin

2 x board connector (case material = B)

Cable length in meters: 0.5 m

1 m

2 m

Circuit board version

x m (lengths on request)

Galvanic isolation: -VS = CAN_GND = shield/case

-VS = CAN_GND ≠ shield/cover

-VS ≠ CAN_GND ≠ shield/cover

Interface: CANopen

CANopen Security

Electrical and/or mechanical variant: Standard

Keep pressure fluctuations under control and ensure consistent flow with ease

Do you want your industrial washing systems to maintain constant water pressure for uniform cleanliness?

Do you want to ensure that the vines at the bottom of the mountain receive the same amount of water as the vines at the top?

Are you looking to save water and energy in your operations?

Then our flow restrictors are the solution.

Our purely mechanical flow limiters "Made in Germany" regulate flows from 1 to 420 liters per minute, withstand temperatures from -20 °C to 200 °C.

LIGHT FOR THE FOOD, BEVERAGE AND PACKAGING INDUSTRY FROM LED2WORK

Robust LED lights ideal for food and drinks.

In addition to lighting operations and work spaces, our LED lights are increasingly used for camera surveillance. The flicker-free light of the lamps is particularly impressive thanks to the high brightness and homogeneous illumination. The observation radius of the camera is optimally illuminated, and the lights can also be clocked using PWM if desired.

An ideal solution for use in food and beverages.

Chemical-resistant, hygienic and safe thanks to the use of FDA-compliant materials: With our standard LED lights INROLED_25, INROLED_50, as well as OEM versions in stainless steel, we offer ideal lighting for sensitive areas in food and beverage. Our LED lights have been adopted by food manufacturers, pharmaceutical packaging manufacturers and even in medical technology as an economical alternative to previous lighting technology.

Rotor hub sensor NBT-D/S3 SIL2/PLd from TWK

The NBT-D/S3 rotor hub sensor is used to measure the rotor rotation speed, e.g. shaft. By combining a tilt and rotation rate sensor in a MEMS design, rotation rates are measured without the sensor being rigidly coupled to the rotation axis. The filter's special mathematical functions result in a very accurate rotational speed signal that is independent of noise, acceleration and temperature and can be used for safe rotational monitoring and control. This makes the sensor a low-cost and easy-to-install alternative to many common magnetic strip sensors and add-on sensors with complex mounting.

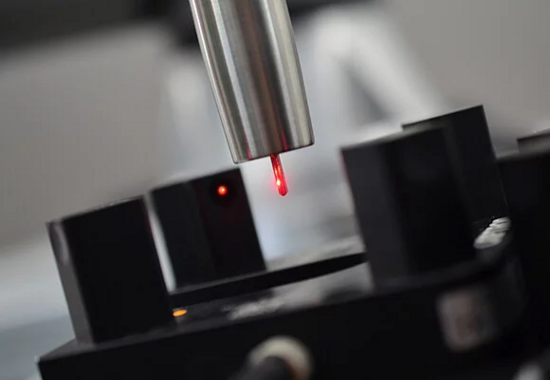

MAXIMUM ACCURACY, MINIMUM EFFORT: AUTOMATIC TCP CALIBRATION FOR YOUR COBOT UR by CAPTRON

In precision robotics applications such as dispensing, welding, and bonding, wear and tear can alter the accuracy of robots.

To minimize production downtime and ensure maximum accuracy, the tool tip needs to be regularly checked and recalibrated. This is especially important after a tool change, after every maintenance, at the beginning of a work shift or even after every process cycle.

Advantages of automatic TCP calibration:

- Minimize downtime: Automated processes reduce production interruptions.

- Increased accuracy and quality: Regular checks and calibration ensure the highest accuracy of your robotic application.

- Reduction of waste and additional work: Accurate calibration minimizes errors, collisions and deviations in the production process.

- Reliable tool change: A quick calibration routine ensures correct tool change.

- Unrivaled speed: Avoid manual recalibration with automatic recalibration.

Our solution for smooth processes: Automatic tool center point calibration (TCP) for UR cobots. With our newly developed URCap software, you can reduce sources of error and avoid wasted time in applications such as welding, dispensing, gluing...

Predefined motion sequences and control commands simplify programming. Our system has been tested and certified by UR.

For more information on product upgrades, downloads and videos on how to use the software, please visit the following link: Automatic TCP Calibration by UR Robots

LED lights for machines from the company LED2WORK

Machine lights for harsh and extreme environments

Machine lighting presents highly specialized challenges: machine lights must be able to withstand mechanical influences and extreme temperatures. In addition, liquids such as oils and emulsions must not damage the lights. LED2WORK GmbH specializes in exactly these requirements and has many years of experience as a manufacturer of LED lights for machines. Our machine lights have a high degree of protection to provide reliable and safe lighting. The company's range includes LED recessed lights, LED surface lights and LED signal lights. The use of the latest LED technology and high-quality processing guarantees a long service life of the machine's lights, which makes them maintenance-free.

Machine lights of the highest quality standards

Durable, indestructible, durable, easy to install and bright - these are the five characteristics that count when it comes to lighting machines. As specialists in this field, we have designed our lamps accordingly.

LIGHTING CHARACTERISTICS AND KEY SPECIFICATIONS

- Extremely durable covers made of metal, mostly aluminum

- Safety glass covers

- Viton® seals with a high level of protection

- High performance LED chips

- Reflector function or uniform illumination of an area

- Suitable for installation in very confined spaces

- Resistant to shocks and vibrations

- Service life > 50,000 to > 60,000 operating hours

- High energy efficiency thanks to LED chips

- No maintenance times; absolutely maintenance-free

- Warranty 36 months

- Protection class III with 24V DC connection

- Protection class I with 220-240V AC connection

- Simple retrofitting into existing machines

- Daylight white 5200K - 5700K

- Electrically chainable (cascading machine lights)

PDE – DIFFERENTIAL PRESSURE SWITCH ELETTROTEC

The new PDEs have been designed to provide excellent performance even in demanding industrial environments. They are used as indicators of clogging of pressure filters in plumbing, but they can also be used where it is necessary to maintain the pressure difference between two branches within certain limits. The IP67 degree of protection protects the electrical contacts even during temporary submersion, while the grounding in accordance with the EU ISO 2014/35 standard makes the products safe in civil and industrial applications In addition to the standard design, there are gold electrical contacts used for low currents or reinforced for high currents. Fluid direction, thread, cartridge size and switching pressure are completely at the customer's choice.

FMX... VR – OXYGEN FLOW METERS WITH VARIABLE SURFACE (PANEL FLOW METERS WITH REGULATORY VALVE) from elettrotec

The FMX series flowmeter is used for measurement and control single-phase non-pulsating unidirectional flow of oxygen.

Thanks to the flow control valve, it is possible to adjust flow rate to the desired value. These flowmeters have acrylic body with screen-printed scale, stainless steel steel fittings, agate stone float and gasket available in FKM

NEW PRESSURE SENSORS from the company elettrotec

New pressure transducers - Elettrotec

The new PTE – PTL – PTH pressure transmitters have been designed for a wide range of industrial applications with a pressure range from 1 to 1000 bar and temperatures from -40°C to +135°C.

New transducers with electrical connection such as M12, Mini-DIN 43650 and DIN are suitable for measuring different liquids such as oil, water, air and water-glycol.

Through a PLC or digital player, the output signal is constantly controlled thanks to the analog 4 / 20 mA or 0 / 10V analog output signal.

Made of AISI 316 stainless steel, they are used in many industries such as agricultural machinery, food and pharmaceutical, machine tools, oil and gas, pneumatic applications and elevators

Accurate and efficient: the new duo of dynamic tilt sensors N6/N7 from elobau

Our new N6/N7 dynamic tilt sensors open up new possibilities for manufacturers in the field. They ensure the highest level of safety and also make the work performance of mobile machines even more efficient.

The N6 static and N7 dynamic, which are based on non-contact MEMS technology, are ideal for use in off-road areas. The principle of operation offers many advantages: both N6 static and N7 dynamic continuously monitor the angle of inclination of the object to gravity, thus reliably providing information for the safe control and movement of your work machines. It performs several important functions at once, such as:

- Cabin level check

- Automatic slope slope compensation

- measuring the position and inclination of moving parts of the vehicle and machines,

- such as an excavator boom

- Stabilization and protection against tilting by monitoring the inclination of the vehicle

In this way, accidents are prevented and users of work machines are optimally protected.

In addition, the new static tilt sensors N6 and dynamic tilt sensors N7 support manufacturers in the off-road vehicle sector with their ever-increasing demands: they enable a higher degree of machine automation and the use of various assistance systems.

In this way, tilt sensors significantly contribute to increasing the efficiency and productivity of mobile machines.

Discover the benefits of our new generation of tilt sensors: static analog CAN and N6 static analog N6 (for high accuracy in static applications) and dynamic CAN N7 (ideal for dynamic mobile machines) are now available.

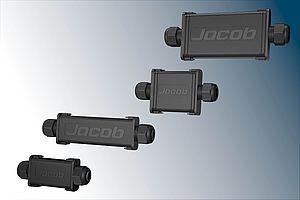

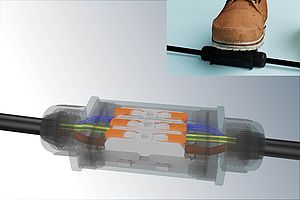

JCC NEW JACOB CABLE CONNECTOR

The Jacob JCC cable connector is used to connect two cables easily and quickly. It combines the proven technology of the Jacob PERFECT cable gland and the WAGO power connector.

JCC is available in 4 sizes, for 3-core and 5-core cables with single and double strain relief.

Inside, proven WAGO technology is available with a choice of 3 or 5 pass-through connectors. Thanks to the snap-in function, cable installation is quick, easy and safe.

In addition to strain relief, the PERFECT cap nuts provide automatic integrated cable protection against rotation.

The robust case is made of polyamide reinforced with glass fibers and is absolutely non-slip. It permanently protects the electrical connection from moisture, dust and other foreign objects.

The JCC achieves an IP68 rating without additional sealing materials.

It covers the temperature range from -25 °C to +85 °C.

Thanks to the flat design, the cable connector can be used in a variety of ways: in installation channels, engineering, building technology, lighting installations, event technology and trade fair construction, to name just a few examples.

Recording of dynamic processes - with PULSOTRONIC strain gauge sensors

Monitoring of shrinkage and compressions applied according to specific customer requirements – DMS Sensoren (pulsotronic.de)

At first glance, some constructions and processes seem rather static - a mistake if the viewer can outwit the inertia of the human eye. Movements are the result of forces and can have devastating effects on the operation and safety of machines and systems, even in microscopic doses.

Sensors to control tension and compression continuously and reliably monitor these minimalist deformations even in harsh and mobile environments.

An excellent feature of strain gauges (DMS) from Pulsotronic GmbH & Co. KG is a customized adaptation of mechanics and electronics to a customer-specific customer application. For this type of measurement task, the more accurate the setting, the more optimal the signal output. Working with the Phoenix contact group, our sensors deliver sensor signals to the cloud in an interface-compatible and processed manner.

Use our nearly 20-year know-how in the field of design and development of strain gauges and ask us for support in solving your monitoring processes.

Encoder TRK38/S3 SIL2/PLd from TWK

Information about the product "Encoder TRK38/S3 SIL2/PLd"

Housing made of aluminum - Stainless steel shaft - Magnetic sensor system - Electrical connection via plug or cable socket. TRK series encoders are equipped with an EtherCAT interface according to IEC 61158-2 to 6 and the CiA DSP406 encoder profile. In addition to redundant sensor technology, the TRK/S3 includes additional internal monitoring measures to achieve SIL2 level as well as safe communication via FSoE-Pr (Failsafe over EtherCAT). The FSoE protocol is designed in accordance with the Safety over EtherCAT ETG.5100 version 1.2.0 specification.

A detailed description of integration and commissioning in the EtherCAT network can be found in the TRK/S3 13349 manual.

- Product category: Encoder

- Single-oder Multiturn: Singleturn

- Single or multi-turn: Single turn

- Version: 38 mm

- Flange and shaft: Synchro flange, 6mm shaft with hole for threaded pin

- Case material: aluminum

- Resolution: 65536 steps/360° <)

- Code type: Binary

- Profile: FSoE, non-certified sample devices

- FSoE, SIL2 certification

- Electrical connection: 1x M12 connector, 12 pin, coded in the letter A, axial

- Interface: EtherCAT FSoE

- Electrical and/or mechanical variant: standard

- Certification: SIL

DISCOVER THE NEW EPX02 PRESSURE SENSOR from elettrotec

The new EPX02 pressure transmitter features significant improvements compared to the previous EPX01 version.

The EPX02 design has been completely redesigned to provide greater compactness and modernity; The head is now 330° adjustable, making it easier to use and install. EPX02 is equipped with a new LCD display, through which it is possible to configure up to two alarms, both at the point of intervention and at the reset point, which effectively allows the setting of differentials. They can be connected in PNP or NPN mode according to the user's discretion; electrical output at 4-20 mA or 0-10 V is provided via a 5-pin M12 x1.5 connector. As the detection element, we use a sophisticated industrial ARM MCU microcontroller and a high-quality ceramic pressure sensor resistant to shock and vibration. EPX02 is used in pressure regulation and monitoring in hydraulic and pneumatic systems, pumps and compressors.

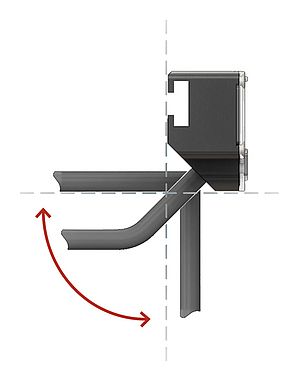

CENALED SPOT Gelenkarm (articulated arm)

CENALED SPOT Gelenkarm (articulated arm), movable LED light with a screw base and 30° optics for a wider spot light. The case of this extraordinary series of lamps is made of aluminum with powder coating. The stable articulated arms are 350 mm / 400 mm long, which allows an extension of almost 80 cm. The LED technology in the lamp head is protected by almost 4 mm safety glass, which meets the requirements for an approved high degree of protection. Economical high-performance LEDs ensure a light efficiency of 134 Im/W, which is exceptional in this class.

CENALED SPOT is available for machine connection with 24V DC and for direct connection with 100-305V AC. The connecting cables leading from the LED lamp are 3 m long.

The CENALED SPOT is equipped with a screw base as standard. As a non-destructive installation option, the lamp can be screwed onto an optional magnetic holder and fixed to all magnetically adhesive surfaces.

Absolute coder KIT TKN/S4 from TWK

The TKN/S4 model is a new generation of bearingless sensors that offers functional safety according to IEC 61508: SIL2 and ISO 13849: PLd in a cost-effective design. The flat housing with cable outlet offers a CANopen or CANopen Safety interface. Versions of the board without cover are available on request. The position magnet is mechanically connected to the application, i.e. mounted on an application shaft or other moving part. The TKN case is placed in front of the magnet. The wear-free device can be easily integrated into existing applications with limited installation space for safe position and velocity measurement. Product category: rotary encoder Incremental or absolute: Absolute Design: 55 mm Mechanical connection: Mounting through through holes Ø 5.5 Housing material: aluminum 3.2315 Stainless steel 1.4404 plastic PCB without cover on request

Resolution:

- 4096 steps/revolution 12 bit

- 8192 steps/revolution 13 bits

- 16384 steps/revolution 14 bits

- 32,768 steps/revolution 15 bits

- 65536 steps/revolution 16 bits

Code type: Binary

Measuring range in revolutions:

- 1 for single-turn

- 2 to 32768 for multi-turn (2^n steps)

Profile:

- C3: CANopen standard version (DS406, 4.1.0)

- S4: CANopen Safety certification (DS406, 4.1.0)

Electrical connection:

- 1 x open strand cable

- 1 x cable with M12-A plug, 5-pin

- 1 x PCB Connector (Case Material = B)

- 2 x open fiber cable

- 2 x cable with plug/socket M12-A, 5-pin

- 2 x board connector (case material = B)

Cable length in meters:

- 0.5 m

- 1 m

- 2 m

- Platinum version

- x m (lengths on request)

Galvanic separation:

- -VS = CAN_GND = shield/case

- -VS = CAN_GND ≠ shield/cover

- -VS ≠ CAN_GND ≠ shield/cover

Interface: CANopen

Electrical and/or mechanical variant: Standard

TUBELED_40 II

The same performance, but more advantages: We have improved the original LED lighting of the TUBELED_40 II machine with more lumens/watt. Yes, originally the first 40mm machine light now comes with more lumens - for more efficiency, more light, better illumination - with the same power consumption.

Renewed: Every TUBELED_40 II shines brighter, doesn't need more electricity - all for the same price.

LED flexible shoulder light from LED2WORK CENALED FLOOD

Wide emitting work light, flexible for different applications

CENALED FLOOD is a practical LED lamp with a flexible arm for various work environments, as it can be used both stationary and temporary. The flexible arm and swivel joint on the bulb head allow for flexible directing of the light where it is needed.

CENALED FLOOD is part of the CENALED modular system. Made in Germany with standardized die-cast aluminum parts and the latest technology.

YOUR BENEFITS

Bright and energy-saving

Wide coverage: unlike spotlights, larger areas can be clearly illuminated.

Flexible arm and head joint allow precise and continuous alignment.

On/off and dimming using the buttons on the bulb head

Flexible arm with protective coating against oil and coolant.

Screw base for attachment or optional accessories such as adhesive magnet, table clamp or wall mount

AREAS OF USE

Craftsmanship, metal fabrication and processing

Workplace in equipment and individual machines

Operation in confined space conditions

Test station

Floor drilling machine

Conventional machine tool

TECHNOLOGY

The latest LED technology with top LED chips

High color reproduction and wide beam angle >100°

Unbreakable safety glass over the light emission on the bulb head

High quality gooseneck - very flexible and oil resistant.

Long life of LED chips

Dimmable using a switch on the lamp head

Made in Germany

EXPLANATION

CENALED FLOOD DC: Protection class IP67 and connection to 24V DC via Ölflex connecting cable, 3m.

CENALED FLOOD AC: Protection class IP65 and connection to mains voltage 100-305V via cable and plug

Towards the future with adaptivity: Why the aISA 2.0 system is so innovative

It was the highlight of the elobau stand at Agritechnica: the aISA adaptive control armrest. The innovative research project combines an operating armrest, tractor and implement, offering implement manufacturers the opportunity to transfer their own operating philosophy to the aISA armrest's haptic operating system.

At this year's Agritechnica, the adaptive armrest was presented for the first time at the elobau stand in a completely new design and with many new adaptive features as part of the aISA 2.0 system for an international audience. The response was very positive. The advantages of the innovative armrest speak for themselves: the aISA system enables a new level of user-friendliness by allowing the tool (aISA Client) to configure the multifunctional armrest (aISA HMI) in the tractor according to the needs of the implement's operation. Operating requirements are predefined by the implement manufacturer, transferred to the tractor and specified to the algorithm on the aISA server, setting the aISA HMI to an optimized configuration. This means that the armrest adapts to any tool as soon as it is attached, providing users with an ergonomic interface that matches the work tool. For the first time, an attachment in a tractor can configure haptic control on the multifunctional armrest. These adaptive controls can display function-specific icons and lighting, be hidden if not associated with any function, or resized to ensure movement compatibility with the controlled part of the implement (eg pick-up is controlled up/down). In addition, it is also possible to change their operating characteristics (e.g. several types of AUX-N on one control element). In addition, the aISA system assigns functions that are predefined with a high frequency of use to controls with a high ergonomic value.

The communication of the aISA system is based on the ISOBUS standard with extensions for communication between the client of the aISA elements, the HMI and the server. Coordination between the needs of the aISA client and the resources of the aISA HMI takes place driverless using an algorithm when the client is connected to the tractor. If necessary, the driver can change the function assignment of the algorithm.

A top team of experts and supporters is behind the development of the aISA system. The project consortium in the follow-up project aISA 2.0 consists of five members: The project consortium was coordinated by the research and teaching area of technical design at the Institute of Construction Technology and Technical Design (IKTD) at the University of Stuttgart. Together with the Institute of Agricultural Engineering at the University of Hohenheim (ATH) and the company elobau, IKTD has already completed a previous project (aISA) in question. In the aISA 2.0 project, they were also strengthened by the association Kompetenčné centrum ISOBUS e.V. from Osnabrück and tractor manufacturer Same Deutz-Fahr. The agency implementing the project is the Federal Office for Agriculture and Food (BLE). The project was financed from the special purpose fund of the federal government in the Agricultural Pension Bank and the innovation fund.

In an expert interview with Tim Schempp, head of advanced development at elobau and project manager of aISA, we again got a very personal explanation of what makes aISA System 2.0 special and how it differs from the previous aISA 1.0 project.

BHyT series: Fuel Cell Hydrogen pressure transmitter from Barksdale

Description:

Our latest design responds to the industry's need for an accurate and reliable pressure transducer for hydrogen applications that mitigates hydrogen intrusion, embrittlement and leaks and provides long-term safety and stability even at high pressures. The compact monolithic design of our BHyT Cell hydrogen pressure transducers is designed for fuel cell applications where space is at a premium while offering reliability in high pressure applications. The BHyT transmitter is designed to maintain stability over the entire pressure range, reducing downtime, maintenance and calibration costs.

Features:

Advanced ASIC sensor signal conditioning ensures high accuracy of 0.25% and low offset error at zero pressure.

It offers a wide operating temperature range of -40C to +100C and an IP67 waterproof rating and compatibility with demanding media such as H2 and O2.

Excellent IEC61000 EMC/EMI protection and thermally compensated sensors ensure high accuracy over a wide temperature range to mitigate thermal errors on sensitive components

It has the ability to measure pressure ranges from vacuum to 10,000 psi (650 bar)

Applications:

Hydrogen fuel cell

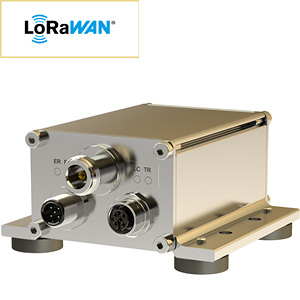

We are pleased to present you our new product newsletter, which focuses on some of our latest highlights in the field of functional safety. Find out more about our CANopen Safety SIL3 encoder with 16 bit resolution and our ultra-compact SIL2 encoder with FSoE interface. We also present our SIL2 cam switch with IO-Link encoder and UL certification as well as our LoRaWAN vibration sensor.

Stay up to date and discover our latest technical highlights!

Multiturn rotary encoder TRSN42/S4 SIL3

SIL3 certified and ASIL D compliant: CANopen Safety encoder with 16 bit resolution. Available as singleturn or multiturn with only 42 mm diameter.

MORE NEWS

Safety in a small format: Ultra-compact SIL2 rotary encoder for safe monitoring of positions and speeds via Failsafe over EtherCAT.

Reliability meets efficiency: Find out more about our compact and backlash-free SIL2 cam switch with IO-Link interface and UL certification.

Ideal for condition monitoring during the construction phase: Vibration sensor with wireless LoRaWAN interface and very low power consumption.

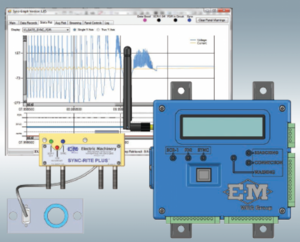

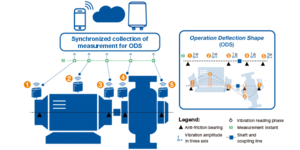

WEGscan

Good results are achieved with technological intelligence. That's why we developed WEGscan, which meets the needs of companies and industries with maximum accuracy and reliability. The modular, versatile and multi-purpose sensor can be connected to different types of equipment and assets, automatically collect data and perform online monitoring.

Tracking options with WEGscan:

- Remote control for updating, measuring and setting

- Integrated with WEG digital solutions

- Versatile and multi-purpose solution

- WEGsync: synchronized measurement of multiple sensors for structural vibration analysis

- WEGsense: technology to detect incipient mechanical failures such as poor lubrication

- Intelligent management is possible with WEG Motion Fleet Management

Designed to transform technology into a strategic advantage, WEGscan carries WEG's technological expertise, integrating hardware and software that connects your production line with Industry 4.0, optimizes assets, increases operational efficiency and supports your growth.

WEGscan can be used in

- gearboxes, gear motors,

- pumps,

- compressors,

- electric motors,

- fans, exhaust fans,

- conveyors

- any type of industry or installation.

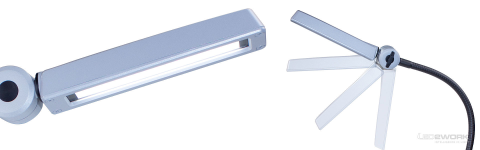

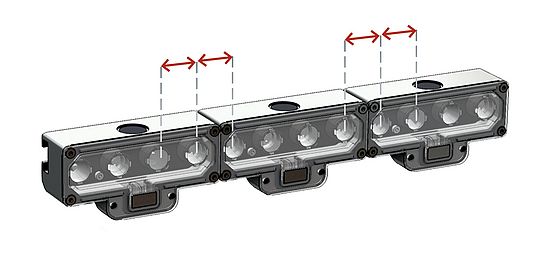

TPL Vision are excited to announce the newest addition to the modular range, the Modular Tiny Bar Light (M-TBAR for short). The M-TBAR is our newest versatile & flexible bar light designed to advance small-scale machine vision applications requiring robust illumination.

KEY FEATURES

Compact bar light suited to machine vision applications in confined spaces - from traceability&code reading, quality control, robotics and more

Built-in modularity with TPL Vision's Angle Changers: customise the beam angle to best suit your application needs

Designed for easy integration with robust IP67 packaging, current control integrated onto cable & standard M12 5-pin connector

Angle Changer Compatibility

Clip on the Angle Changers to widen the beam angle - it's that simple!

The Angle Changers allow you to experiment or adjust your illumination if your project changes

No need to dismantle your product: keep the M-TBAR's IP67 rating

Easy-chain together with no change to LED spacing

Chain together several M-TBARs to mimic the effect of using a longer bar light with no change in LED spacing distance.

Flexibility & easy integration

- Compact dimensions

- Cable mounting flexibility to suit confined space applications

- Easy T-SLOT mounting

- Integrated current control

- Powerful OverDrive

We're pleased to bring you our latest product newsletter, which focuses on some of our latest highlights. Find out more about our SIL2-certified encoder with 16-bit resolution, the ultra-compact SIL2 encoder and our multi-turn and single-turn encoders with ASIL-D conformity. Finally, we recommend taking a look at our inclinometers with PROFIsafe or CANopen safety interface for dynamically moving applications.

Safe position and speed: Discover our SIL2-certified PROFIsafe encoder with 16-bit resolution.

Safety in small format: ultra-compact SIL2 rotary encoder for safe monitoring of positions and speeds with FSoE.

Reliability meets efficiency: Find out more about our multi- or single-turn encoders with SIL3 certification and CANopen Safety.

Reliable precision: Position measurement with our CANopen Safety or PROFIsafe inclination sensor for dynamically moving applications.

OVERVIEW OF AVAILABLE INTERFACES

Basically, we serve all industry standards depending on the model you choose. The required interface is not included? Not a problem

LED customer designs, LED OEM solutions from LED2WORK

From idea to series production - OEM and special solutions

In addition to our range of standard luminaires, we also focus on bespoke LED products that are designed and manufactured to meet specific requirements. We can help you realize the exact product you need for your project to meet your technical lighting needs, your time frame and your business requirements.

REFERENCE LIGHT, WIDE SPOT LIGHT OR SOMETHING BRAND NEW?

In order to turn such new ideas into products, we boast extensive expertise, in-house prototyping and the capacity required for subsequent expert manufacturing and assembly. The result is an efficient, economical process chain: from the concept phase through prototyping to the delivery of customized serial components.

Regardless of whether it is a small series or several thousand pieces - at the end of the day, it is always the intelligent implementation of customer requirements and our high quality standards that make us stand out. It also means we are a great partner for OEMs who have fixtures and lighting in their own products or want to incorporate them in the future.

Full-surface LED signal light CSL6 from CAPTRON

Description

The full-surface LED signal light CSL6 from CAPTRON shines with 96 bright LEDs in red and yellow. CSL6 is intended for adhesive mounting on single and double glazing.

No disc hole required for installation. The signal light can be simply clicked into the mounting flange. For flexible positioning of the CSL6 on the window profile, we also offer corner mounting and beveling of the profile.

We make the cover from polycarbonate. The front is impact-resistant and can be cleaned with a high-pressure cleaner (protection class IK 08 or IP 69K). Their maintenance- and wear-free construction is designed for continuous daily use and withstands even the most adverse environmental influences such as heat and cold, as well as industrial influences such as dirt, dust and chemicals.

Thanks to LED technology, it is possible to achieve a lifetime of up to 100,000 hours, which corresponds to eleven years of continuous operation

Important features

- Large illuminated area Ø 55 mm

- The electronics and the lamp are molded waterproof

- Extremely long service life of up to 100,000 hours

- Energy-saving, maintenance-free, wear-free

- 100% water and oil resistant / vandal resistant

- Protection class IP 69K, impact and scratch resistant IK08

- lighting

- 96 LEDs (red or yellow)

- assembly

- Adhesive mounting behind glass, glass plate or acrylic glass plate

CSL6-2 (default)

LED signal light through the glass

- Light area Ø 55 mm

- adhesive assembly

- Total internal height 14 mm

- Outer height 3.2 mm

- Profile inclination 90°

APPLICATION: TRANSPORT AND TRANSPORT | BUILDING TECHNOLOGY

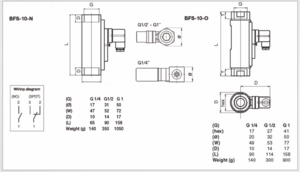

Flow meter for explosive environment BFS-10-N / EXI from Barksdale

Measurement range

0.005...0.06 l/min to 60...150 l/min for water

Operating pressure: up to 350 bar

Operating temperature: up to +160 °C

- Flow switch with and without optical display

- continuously adjustable values

- Robust design

- Low hysteresis

Applications

Measurement and monitoring of liquids, e.g. in cooling systems, test stands, pumping systems, extinguishing spray systems, etc.

INCREASE EFFICIENCY - REDUCE OPERATING COSTS WITH JACOB.

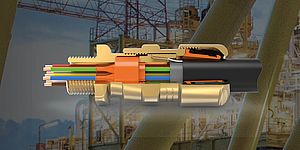

The PSG 553/RAC cable gland series from Hawke International has been re-developed to enable easier and faster installation of barrier cable glands in Ex d applications.

The upgraded products are now using a diaphragm sealing concept that seals the individual cable cores, allowing the user to eliminate the use of potting compound or liquid resin.

The innovative cable glands are available in sizes M16 to M32 and ½“NPT to 1 ¼“NPT.

PRODUCT FEATURES

- Immediate barrier sealing of the individual cores through innovative diaphram sealing concept

- Sealing insert designed for 4, 7, 12 and 19-core cables (depending on the size of the cable gland)

- A sealing range with a diameter of 1.5 mm to 4 mm enables the installation of single-wire cross-sections up to 2.5 mm²

- The alternative sealing insert for the size M25 cable gland enables the sealing of 5 single cores with a core diameter of up to 6.5 mm

- Sealing of shrinked drain wires possible

- More environmentally friendly solution compared to previously used epoxy resin

- No shipping restrictions like a traditional epoxy barrier cable gland