Increase machine performance with powerful, highly scalable control

Thursday, October 17, 2024, 11:00 a.m. ET

Register for the live session or to receive a link to the recording

Discover the next generation of motion control. Our new PCMM2G controller offers significantly higher performance, scalability from 1 to 64 axes of motion, and simple integration in a compact package. Join us for a revealing online tour.

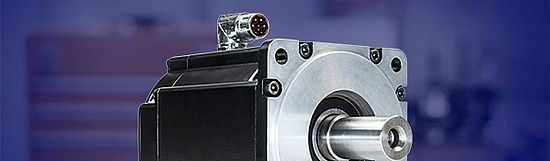

MAC231-P IP67/69K Stainless Steel Integrated DC Servo Motor for Harsh Environment JVL

MAC231 motor - with a new generation encoder with unlimited downtime, no battery required!

JVL is proud to announce the brand new generation of our IP67 320W RMS, S3 25% duty cycle servo motor. Protected against high pressure and high temperatures, this new engine is based on previous designs and customer feedback collected over many years, and offers a wide variety of options and options that make this product suitable for almost any application.

Key Features:

IP69K optional

Highly dynamic servo controller

Industrial Ethernet - 6 protocols

Absolute multi-turn encoder with unlimited downtime (no battery!)

Recommended supply voltage 48 VDC

1 kW Top performance

Position accuracy ±0.4° (±9.1 pulses) thanks to the magnetic encoder

Optional built-in gearbox for torque up to 50 Nm.

Protection class up to IP67

A wide program of optional modules

Connectors: industrial M12

Built-in ePLC PLC

What's new?

Absolute multi-turn encoder based on collection technology without battery or device

High performance Ethernet similar to larger MAC engines

New MOSFET technology for higher efficiency and cooler motor

Encoder resolution 8192 CPR (higher resolutions planned)

Options:

STO and/or brake connector

More advanced FOC filter for lower noise and better engine performance

100% stainless steel shaft, flange, tube and rear end cap.

Special Teflon seal for long-term waterproof operation.

Cost effective in harsh wet corrosive environments

A shaft seal and leak-proof cable glands provide a watertight seal at both ends.

Ideal for food, liquid, pharmaceutical, washing, chemical, bakery and beverage machinery, etc.

Option for a built-in planetary gearbox.

Option for embedded PLC, RS232/485, Profibus, CANbus or industrial Ethernet (EtherCAT, EtherNet/IP, Profinet, Modbus TCP, Sercos III and others)

Efficient and Effective Risk Management for Vertical Axes

With new safety standards that require periodic brake testing and prohibit embedding of test functions within standard controls, what’s the best way to keep operators safe, maximize productivity, and simplify machine design? Learn the advantages of on-drive safety functions.

Motors Designed for the Rigors of Space

With tens of thousands of new satellites in the planning, the rush is on to utilize low Earth orbit. Learn how motors designed for the rigors of space and the realities of the marketplace will be key to winning the new space race.

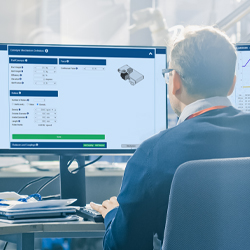

Online, Interactive Product Selectors

From torque, speed and power to form factor, controls and accessories—the perfect fit is key to your application’s success. Use our selection tools to choose motion products with confidence. Our instructional video shows you how simple it can be.

Kollmorgen Announces the New PCMM2G Motion Controller

For simple machines or complex automation environments with up to 64 axes of synchronized motion, Kollmorgen’s new PCMM2G controller introduces next-generation performance and flexibility. It’s simple to use and integrates seamlessly with virtually any system.

PCMM2G: Next-Generation Performance in a Powerful, Compact Controller

Take control. The new PCMM2G automation controller is the simple way to gain greater flexibility, speed and ease of use. It seamlessly integrates with Kollmorgen Automation Suite and even supports third-party devices, providing up to 64 axes of synchronized motion.

Introducing the Next-Gen Motion Controller

Increase machine performance with powerful, highly scalable control

Thursday, October 17, 2024, 11:00 a.m. ET

The new PCMM2G delivers 1.5–3.5 times the performance of previous motion controllers, with scalability to control 1–64 axes of motion. It’s easy to integrate with practically any automation system. Learn more in this online demonstration.

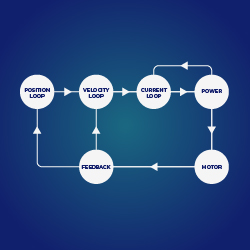

How to Set Servo Motor Phasing for Effective Axis Control Thursday

October 24, 2024, 11:00 a.m. ET

Instead of mechanical commutation, brushless servo motors rely on electronic commutation based on feedback data and motor phasing. Join this online session to learn how to establish the correct phasing between motor and drive for optimum servo control.

How to Set Up Your AKD for Success

October 23, 2024, 11:00 a.m. ET

New to setting up a servo drive? Already experienced but looking for tips for a more effective setup process? This session is for you! Follow along and learn how to minimize setup time, apply best practices, and create precise motion—step by step.

Save My Seat:

Advanced Motion with AKD Thursday

October 24, 2024, 11:00 a.m. ET

Create intricate motion tasks, identify mechanical compliance, and increase performance by mastering the programming and diagnostic tools built into the AKD.

Save My Seat:

Compact Joint Design for the Next Generation of Surgical Robots

In robot-assisted procedures, surgeons value the ability to place multiple instruments in a nearly parallel orientation. Learn how to design compact robotic arm joints that give surgeons the dexterity they need and help improve patient outcomes.

Frameless Motor Performance Curve Generator

Map speed-torque curves based on variables including current, voltage, ambient temperature and winding factors. It’s easy to specify the optimum frameless motor for your application using the online Performance Curve Generator.

Exceptional Motor Performance for Superior Robots

When designing a collaborative robot, you want each joint to deliver optimum torque density and smoothness while keeping size and weight to a minimum. That’s why we designed a new generation of robot-ready frameless motors.

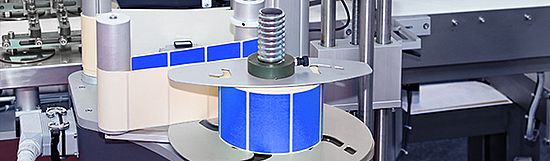

Discover Smarter Packaging Technologies

How can you make your form, fill and seal machine simpler to use and more compact? How can you streamline programming, operation and maintenance? How can you enhance throughput, quality and safety? Read our latest blog to learn about the state of the art in motion for packaging.

Deliver High Performance in a Compact Form with TBM2G Frameless Motors

With significantly higher torque density in a more compact axial design, next-generation TBM2G frameless motors are ready to perform, ready to fit your design, and ready to scale. Learn how you can engineer a more capable machine, without compromise.

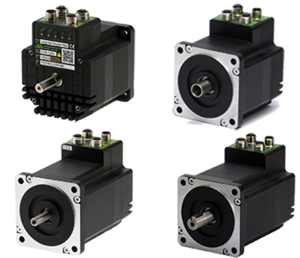

Get Higher Performance in Less Space with AKM2G Servo Motors

Next-generation AKM2G servo motors provide substantial performance improvement without changing the motor mounting or consuming more machine space. And they’re available with a wide range of options including extensive feedback, shaft, connector and support for functional safety.

Experience and Expertise for Defense and Aerospace

In the defense industry, program specifications, contractual obligations and provisioning requirements are far more demanding than most civilian applications. With more than 70 years of serving customers in this industry, Kollmorgen is up to the challenges.

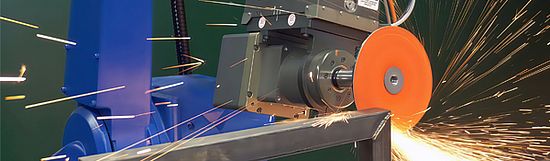

5 Motion Tips for High-Definition Metal Cutting Performance

The success of your metal-cutting machine depends on the performance of its motion systems. Learn how to optimize the fieldbus architecture, control loop bandwidth, servo motor design, feedback system and cabling to achieve superior cutting quality and speed.

Direct Drive Helps Improve the Production Speed and Qualityof Electric Vehicle Batteries

The demand for electric vehicles is soaring. Learn how a major manufacturer of lithium-ion blade battery production equipment significantly increased throughput and quality using direct drive technology to improve its competitive position.

Stop, Hold and Go Safely: Motion Tuning for Vertical Loads

Vertical loads need to be properly managed to avoid the potential for wasted product, operational interruptions or even human injury. Learn best practices for configuring your servo drive’s vertical load handling, including Safe Brake Control and Safe Brake Test functions.

Increase Your Machine’s Accuracy and Reliability with Secondary Feedback

Thursday, September 12, 2024, 11:00 a.m. ET

Complex, high-speed motion axes can often benefit from a secondary feedback device located near the load in addition to standard servo motor feedback. Learn when and how to add secondary feedback for predictable performance under the most demanding conditions.

Save My Seat

The Foundations of Electric Motion

Thursday, September 19, 2024, 11:00 a.m. ET

Learn the details of different motor types, open vs. closed loop control systems, and how to configure the optimum motion system for each machine axis.

Save My Seat

The Foundations of Motor Performance

Friday, September 20, 2024, 11:00 a.m. ET

Join this session to gain the practical knowledge you need to optimize servo performance, including how to specify the right feedback device and resolution, achieve efficient and cost-effective inertia matching, and more.

Save My Seat

What is a Closed-loop System?

When you need the most precise control of torque, speed and/or position, servo motors and drives are likely your best choice. But how exactly does a servo system achieve such precision? Read this brief Q&A to learn the fundamentals of closed-loop control.

Explore the Possibilities of Frameless Servo Motors

The Kollmorgen KBM series enable applications that are lighter, more compact, more precise and better protected from environmental extremes. Learn whether frameless motion is right for you — and how to choose your ideal motor configuration.

Frameless Motors for Gimbal Motion

Multi-axis gimbals for imaging, sensing and communications systems benefit from compact, lightweight, ultraprecise motion. TBM2G frameless, direct-drive motors provide the ideal solution. Learn why and get technical advice for engineering the optimum gimbal design.

Motion Control System Selection in Next-Gen Robotics

Tuesday, August 27, 2024, 2 p.m. ET

Yoshi Umeno, Global Industry Manager - Robotics - Kollmorgen

Greg Harnsberger, Senior Manager of Global Industry Marketing - Portescap

Unlock the full potential of your robotic designs in our upcoming webinar. We'll explore critical factors in motor selection, reveal how to achieve seamless communication with feedback devices, and examine real-world case studies of optimized motion control systems, from collaborative surgical robots to humanoids.

The Right Motor For Tough Conditions

Whether you’re designing for tough medium or heavy washdown applications or all-weather conditions, AKMA motors offer the ideal feature set. See which AKMA motor meets your unique specifications with our streamlined product brochure.

eVTOL Motion, From Design to Delivery

Did you ever imagine you could take an air taxi from the airport to a downtown location? Or see road congestion give way to direct, point-to-point delivery of goods overhead? With innovative eVTOL technology, all this and more could come true sooner than you thought. Learn how Kollmorgen is helping.

Increasing Trajectory Welding Speed in Lithium-Ion Battery Production

Electric vehicles and electronic devices are creating an exponentially growing demand for lithium-ion batteries. Learn how precise laser welding, controlled by Kollmorgen’s direct drive technology, improves control accuracy by 30% and boosts yield to over 99%, substantially improving the competitive position of electric vehicle battery manufacturers.

Exoskeleton Excellence: Greater Comfort, Safety & Mobility

The exoskeleton market is at a tipping point. With an aging population, increases in chronic disease and no end in sight for serious labor shortages, exoskeletons offer tremendous potential. But how will engineers achieve the delicate balance of performance, safety and comfort?

Size Your Motor and Drive in Minutes

Save engineering time and eliminate uncertainty. Motioneering is the guided selection tool that shows you optimum motor and drive choices based on the application requirements you enter. Solve selection and sizing challenges in minutes, automatically.

Surgeons want robotic cameras and instruments to operate as closely together as possible for an accurate field of view and minimal patient trauma. Learn how next-generation frameless motors are advancing the state of the art for high-performance, high-precision robots.

Essentials of Motion Control

Register now and Learn at your convenience

The Essentials of Motion Control self-paced class, allows you to follow the path from electrical energy to physical motion, focusing on every opportunity to optimize motor efficiency and performance. Ready to get moving?

Get Started Now

Stepper Motor or Servo Motor: What are the key factors to consider?

Stepper or servo? It’s one of the most common and important questions in motion engineering. And that’s why we’ve provided answers you can use in one of our most popular white papers ever. Read it, and make the right choice with confidence.

Get the White Paper

Three Design Considerations that Indicate a Machine Needs a Frameless Motor

Does your machine need to operate in a smaller footprint, deliver enhanced performance or endure extreme conditions? Learn why a frameless direct-drive motor is likely your best solution.

Read the Blog

Still Designing to Decades-Old Inertia Matching Rules?

Machine Designers have pursued the idealized 1:1 inertia matching for the motor and load. But what if this rule no longer applied and you could use a significantly smaller motor and still achieve perfect motion? You can, and here’s how.

Get the White Paper

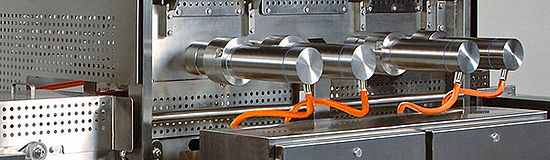

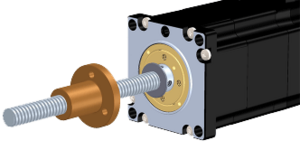

NEMA17 and 23 ball screw stepper actuator with piston rod drive up to 2200 N tip by JVL

Introducing the latest innovation from JVL A/S, a global leader in integrated servo and stepper motors, the ServoStep™ range welcomes a ground-breaking addition: the Piston Captive Style Actuator, also known as the Electric Linear Rod Actuator. Designed with precision and durability in mind, this new drive boasts a built-in high-quality ball screw and non-rotating guide to ensure extended life. Unlike traditional setups, the ball screw is seamlessly integrated into the motor shaft, offering an exceptionally compact solution and shorter drive length.

Linear stepper motors can reduce costs and save space. No coupling, no additional bearing support and no assembly work required. It reduces not only costs and length, but also the failure rate due to fewer components and simpler construction. In applications with low radial load capacity, a linear guide is not required. The special design and use of a ball screw and low-friction guide allows for long life, increased efficiency or reduced maintenance requirements.

Functions:

- Stroke from 12.7 to 127 mm. (custom lengths available)

- Rolled ball screw 1, 2 or 4 mm/rev with C7 accuracy level

- Linear speeds up to 200 mm/s

- Accuracy 0.05 mm

- Non-rotating piston end

- Motor with double-row ball bearing for high axial load and minimum axial play

- Optional epoxy coating for IP65/67 coverage

- Rear brake option

- Ball linear bearing option for high radial loads

- Selection of precision leveler precision ball screws including C0 to C5

- Flexibility to select a customer-specific brand of ball screws

Various configurations are available

Discover unmatched performance and versatility in a variety of configurations. ServoStep™ drives are available in NEMA17 and NEMA23 sizes with plastic nuts with leads from 0.635 to 25.4 mm/rev and forces up to 2500 N. In addition, NEMA34 variants are offered with lead screw pitches from 2.54 to 25.4 mm and 2 or 5 mm/rev ball screw pitches that provide forces up to 4000 N. Alternatively, NEMA34 models are equipped with lead screws with plastic nuts and pitches from 2.54 mm to 25.4 mm that provide forces up to 3000 N.

Understanding Stepper Motor Winding Options: Series vs. Parallel

Thursday, August 15, 2024, 11:00 a.m. ET

Stepper motors can be wound in either a series or parallel configuration, and which style you choose can make a big difference for your application. Learn the nuances of stepper windings and how to make the best choice for different application scenarios.

Save My Seat

How to Use Motioneering to Size Your Application

Wednesday, August 21, 2024, 11:00 a.m. ET

Calculating how servo system components will fit and perform in your application can be a challenge — unless you have the right tool for the job. Take a tour of Motioneering, and learn how to easily create basic motion profiles that can help you make the optimum choices.

Save My Seat

Creating Advanced Motion Profiles

Thursday, August 22, 2024, 11:00 a.m. ET

Size products and create complex motion profiles for additional mechanism types, such as conveyor systems and electric cylinders. This session will teach you best practices you can apply to any motion project.

Save My Seat

Build a Better Humanoid Robot

Humanoid robots must be capable of highly dynamic motion, coordinated across dozens of robotic joints, in order to manipulate objects of varying size and weight while simultaneously carrying their own weight and navigating unpredictable environments. The motion requirements are extremely complex compared to conventional industrial robots. Learn how to understand and solve them.

Minimize Weight and Size to Maximize Efficiency

By specifying lighter, more compact, higher-efficiency motors, you can achieve optimum performance for positioning UAV flight-control surfaces, visualization systems, sensors, payloads and more. Learn how to design a more capable aircraft, bring it to market faster, and support it confidently throughout its lifecycle.

Frameless Motors for Propulsion Systems and Extreme Environments

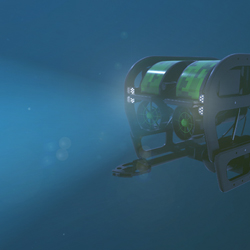

When a housed motor can’t provide the environmental resilience you need in the compact form factor you want, consider embedding a frameless motor into your mechanical design. Gain full control to resist deep ocean pressures, daily washdowns, high vacuum, ionizing radiation and other extreme conditions.

Cartridge DDR: Precise, Powerful, Simple

Direct drive frameless motors offer the ultimate in precision and torque density. But what if you could get these advantages in a motor that installs in minutes? Learn how we combined the performance of a frameless servo motor with the installation simplicity of a housed motor.

Simplify Your 3D CAD Design with these Downloadable Product Models

Simplify and accelerate your machine-design process. With Kollmorgen’s fully configurable 3D CAD models, you can search, configure and visualize more than 50,000 servo motor, drive and controller options, then download your selections for direct incorporation into your CAD design.

Enhancing Precision While Reducing Size, Weight and Cost

Learn how a manufacturer doubled the capacity of its precision laser-cutting machine without increasing the footprint — then expanded its market with a lower-cost version that still delivers excellent performance. What will your next machine be capable of?

July Training Events

Register for the live session or to receive a link to the recording

Unlock the Secrets of Effortless Motion Control Programming

Thursday, July 11, 2024, 11:00 a.m. ET

Ever wish you could have one seamless tool for creating complex motion tasks — with integrated PLC programming languages, graphical definition of multi–axis relationships, simulated motion testing and more? Now you can. Take this tour to see how it all works.

Save My Seat

AKD BASIC Program Language Setup

Wednesday, July 17, 2024, 11:00 a.m. ET

Learn the easy way to set up and test motion programs on your AKD BASIC servo drive. Get a complete tour of our powerful Workbench software in this online training session.

Save My Seat

AKD BASIC Advanced Programming Loops

Thursday, July 18, 2024, 11:00 a.m. ET

Your AKD BASIC servo drive is capable of much more than basic motion tasks. Go online and learn how to create if…then…else and other conditional statements, create embedded loops, program interrupts and more using our powerful Workbench software.

Save My Seat

Resolving Servo Feedback Choices

Thursday, July 25, 2024, 11:00 a.m. ET

A servo system can only be as precise as the feedback device. Making the wrong choice for your application can have devastating effects. Learn the operating principles and the pros and cons of each option, so you can achieve top performance with confidence.

Save My Seat

How to Ensure Motor Compliance in Exoskeleton Design

In the ever-changing field of robotics and wearable technology, exoskeletons hold growing promise in several applications — but bringing them to life can be challenging. That’s where optimized motor design comes in.

Tips for Selecting Stepper Motors and Drives

On Demand

You’ve determined that a stepper motor is the right technology for your application, but how do you choose the optimum motor and drive combination? With so many available options, this online session will explore the differentiating features and give you the selection tools and tips you need to make the right choice with confidence.

Enabling a New Standard of Performance for Stepper Motors

The P8000 series stepper drives deliver smooth, quiet motion across the full speed range — ideal for labelers, indexers, CNC machines, packaging machines, pumps and other applications requiring low-speed, point-to-point motion control for fixed loads.

PMX: The No-Compromise Stepper

When your design calls for high torque and perfect fit in a stepper motor, it calls for the PMX series. These motors offer great performance and quality in a wide range of standard frame sizes and standard options—all at a very affordable price point.

Optimize Your Stepper Now

Choose the right frame size, matched to your voltage, torque and speed requirements. It’s simple to get the application-specific performance you need with this online design tool. Try it.

5 Critical Insights: Interpreting the Bode Plot

Bode plots reveal the unique frequency-response fingerprint of servo mechanisms. But how can you read the fingerprint and use it to fine-tune your system? Optimize machine motion by unlocking these five key Bode plot insights—complete with illustrated examples.

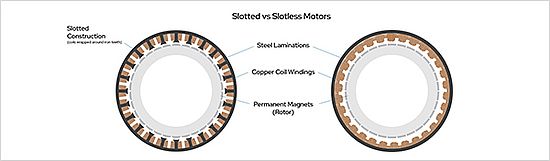

Motor Windings: Understand How They Work and Affect Performance

Friday, June 21, 2024, 11 a.m. ET

To maximize your application’s motion performance, specify the optimum servo motor. Stator windings play a major role in determining motor torque, velocity and horsepower. Join us online to enhance your engineering skills through an in-depth knowledge of motor windings.

Save My Seat

AKD2G Drive Quick Setup Guidance

Wednesday, June 12, 2024, 11 a.m. ET

Join our online Mentor Session series to learn the quickest, most effective procedures for setting up and programming your AKD2G servo drive using our Workbench software. Accelerate your path to productivity.

Save My Seat

Advanced Configuration for AKD2G Dual–Axis Drives

Thursday, June 13, 2024, 11 a.m. ET

Unlock the power of your dual-axis AKD2G drive, including triggering multiple motion commands with a single input, setting up functional safety features and much more. Join this informative online session, and master advanced dual-axis motion tasks.

Save My Seat

See Exactly How Your Motor Will Perform

With just a few clicks, our Performance Curve Generator graphs the continuous torque, peak torque at different temperatures, and torque/speed characteristics of all our housed motors. There’s never been an easier way to evaluate the optimum motor for your application environment.

Building a Successful Surgical Robotics Company Through Customizable Cobot Design

On Demand

Join Dr. Jindong Tan, the President and Founder Azure Medical Innovation, along with Gene Matthews, Kollmorgen Senior Product Manager as they discuss navigating through the unique challenges that are presented in the surgical collaborative robotics market. They will explore critical engineering considerations when specifying surgical application needs regarding collaborative features, AI integration in the surgical flow, and certification requirements.

AKM2G Servo Motors

Get significantly more torque, increased feedback performance, reduced cabling and other next-generation capabilities—without changing your installation footprint. What will these motors do for your machine?

Tips for Scaling Exoskeleton Production

The exoskeleton market has been built on smaller volumes and custom production. But as the industry shifts — and exoskeletons become more common and viable for everything from medical rehabilitation and mobility to heavy load lifting — OEMs should be smart about the transition to efficient, high-volume production.

Motors Designed to Win the New Space Race

From powerful motors that move massive ground station antennas to radiation-hardened and outgassing-resistant motors for satellites and spacecraft, Kollmorgen supplies motors that deliver reliable motion in the most challenging space applications.

Automating Systems for Metal Forming

A builder of automated tube-cutting machines increased productivity by 20%, completely eliminated manual adjustments, and achieved unprecedented versatility to serve wide-ranging market needs. Learn how motion can transform your metal-forming machine.

Clean Mirrors for Clean Energy

To keep energy flowing, heliostat solar plants need to keep thousands of massive mirrors clean. Learn how Kollmorgen motion helps increase maintenance efficiency by 500% and cleaning efficiency by 2,400% while operating in unpredictable terrain at temperatures often below –30ºC.

Tips for Selecting Stepper Motors and Drives

You’ve determined that a stepper motor is the right technology for your application, but how do you choose the optimum motor and drive combination? With so many available options, this online session will explore the differentiating features and give you the selection tools and tips you need to make the right choice with confidence.

The Difference Between Continuous Ratings and Holding Continuous Loads

When a motion application requires holding a load in position for an extended time period, engineers encounter a lot of confusion around words like “stall” and a lot of uncertainty about proper servo motor sizing. Get clear answers and practical advice to ensure the success of your application.

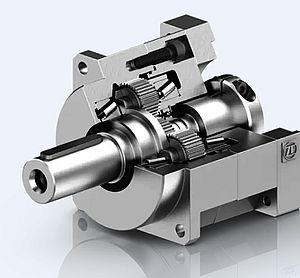

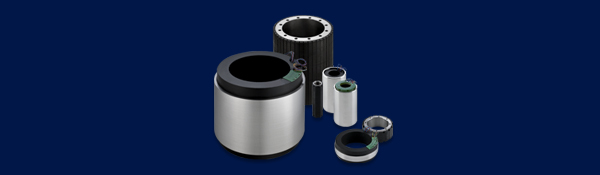

ZF Servoplan - planetary gearbox

For a wide range of applications in engineering, ZF offers a complete range of planetary gearboxes for a wide range of applications and always perfectly adapted to the intended purpose.

What can Servoplan - planetary gearbox provide?

Servo-controlled transmissions can be used in several contexts. Single-speed and two-speed servo drives with ZF Servoplan gearboxes are used wherever highly dynamic and precise positioning is required. Target output torques of 25 - 3,000 Nm are possible with different model sizes. Planetary gear sets for servo motors are used in packaging technology, in forming technology, as well as in general for machinery and equipment.

Advantages:

- Special galvanic surface

- Permissible high acceleration torque

- Low gearbox temperatures and minimal power loss

- Without will

- Compact design

- Robust shaft seals ensure a permanent and secure seal

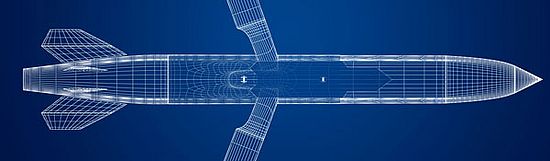

Motion for Missiles: From Speed of Innovation to Speed of Production

The worldwide demand for rockets and missiles is rapidly growing, and the most innovative designs will lead the market. How can you accelerate development of mission-critical guidance and control systems that depend on highly specialized motion systems? Kollmorgen has answers.

Improve Flexographic Printing Performance

Flexographic printing has advanced significantly, but there remains untapped opportunity. Perfect motion synchronization can ensure consistent web tensioning, precise registration and steady repeat lengths. Learn how to apply direct drive technology to deliver higher-quality print jobs, faster.

The Key to Next-Generation Surgical Robots

Surgeons want robotic cameras and instruments to operate as closely together as possible for an accurate field of view and minimal patient trauma. Learn how next-generation frameless motors are advancing the state of the art for high-performance, high-precision robots.

Unlocking Design Possibilities with Frameless Motors

Friday, May 17, 2024, 11 a.m. ET

Frameless motors bring powerful and exciting new possibilities to a wide range of machine designs. Learn how to incorporate this transformational technology into systems that are lighter and more compact, more precise and reliable, and hardened against extreme washdown, underwater, radiation-exposed, high-vacuum and other challenging environments.

Save My Seat

Tips for Selecting Stepper Motors and Drives

Thursday, May 9, 2024, 11 a.m. ET

Stepper systems offer performance and simplicity to suit a wide range of applications but selecting the optimum stepper motor/drive combination can be daunting. Join our online session to delve into the range of stepper technologies, their features and benefits, and the design tools available to help you make the right choice.

Save My Seat

Mastering Dynamic Motion: Revolutionizing Exoskeletons

Wednesday, May 22, 2024, 11 a.m. ET

New innovations in exoskeleton design promise to bring transformative possibilities to military, logistics, healthcare and other applications. Learn how to navigate the unique mobility challenges involved, maximize motor efficiency, and ensure that your motion solution is highly manufacturable and scalable for marketplace success.

Save My Seat

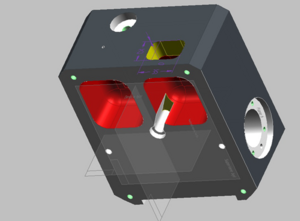

MOOG miniature DC motors.

https://www.moog.com/products/motors-servomotors/brush-motors/cube-torque-brush-dc-motors.html

Our family of miniature permanent magnet cube brush DC motors includes motors available in 0.75 inch and 1 inch frame sizes. These motors are designed to suit a wide range of applications including direct drive servo systems, recorder drives, torque hold and high torque, low speed control systems. It is a motor with fast response at all operating speeds due to its high torque-to-inertia ratio and low self-inductance. Torque increases directly with input current for linearity. As a direct servo drive, it offers high resolution. Its cubic shape allows weight and space savings and easy assembly.

Cube motors are often used in applications where high torque is required but available space is limited. Cube motors are easier to mount than cylinder motors in many applications and are easier to lock into the housing.

Moog offers a choice of Alnico or Samarium Cobalt magnet materials to meet most requirements. These rare earth magnets produce higher magnetic energy per unit volume than most commercially available permanent magnets. Alnico magnets provide increased temperature stability, while Samarium Cobalt magnets offer high energy with good, stable performance.

We are equipped for hundreds of designs with different windings, terminations and other options including gears, brakes, resolvers, encoders and potentiometers. Most of the designs can be easily adapted to different requirements. We can also provide customized engineering services

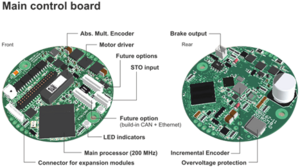

Integrated brushless DC motor MAC320-P for OEM machines from JVL

https://www.jvl.dk/1328/mac320

320 W MAC motor® - Double the power but SAME size - with a new generation absolute multi-turn encoder, based on

Wiegand principle (harvest) where no battery is needed!

JVL has developed a new addition to our Mini-MAC series. Servo motor MAC320 - 320 W.

We have developed our most powerful integrated motor in the NEMA23 size.

The target application is high-performance positioning in a small all-in-one package.

Key features

- Twice the power - but SAME size as the MAC141 (134W)

- Very high torque to volume ratio

- Special DC brushless motor for OEM applications

- 3 times the maximum torque (1 kW)

- Recommended supply voltage 48 VDC from PSU or battery

- An absolute multi-turn encoder option. No battery or equipment required

- Use standard JVL expansion modules for Ethernet, CAN bus and PLC applications

- Option for STO connector

- The ø8 mm shaft can handle higher torque and power

- Position accuracy ±0.065°. With multipole encoder ±0.037°

- Absolute encoder singleturn 13bit. Absolute 19 bit

What is new?

Absolute multi-turn encoder based on collection technology without battery or device

High performance Ethernet similar to larger MAC engines

New MOSFET technology for higher efficiency and cooler motor

Encoder resolution 8192 CPR (higher resolutions planned)

Options: STO and/or brake connector

More advanced FOC filter for lower noise and better engine performance

The high performance is due to the high magnetic forces, which on the one hand create a high torque of the shaft, but the trade-off is a high torque of the gears.

It is therefore not possible to achieve the same level of speed accuracy compared to other MAC engines. This is usually of no consequence for positioning applications.

Design a More Capable UAV

From precise actuation of flight-control surfaces to positioning of visualization systems, payloads and more, the optimum unmanned aerial vehicle design incorporates motors that operate at peak efficiency while minimizing size and weight. Learn how to specify the ideal, flight-worthy motor for each UAV application.

Deliver High Performance in a Compact Form withTBM2G Frameless Motors

With significantly higher torque density in a more compact axial design, next-generation TBM2G frameless motors are ready to perform, ready to fit your design, and ready to scale. Learn how you can engineer a more capable machine, without compromise.

Monitoring and Controlling Brakes Through On-Drive Functional Safety Technology

Without proper brake monitoring and testing, vertical loads can be hazardous. However, ISO 13849-1 does not allow brake testing functions to be embedded into standard machine controls. Learn the simple way to comply while achieving the safety level you need.

Discover the Power of Kollmorgen Automation Suite™

With controllers, drives, motors, communications and programming tools designed to work together, you can engineer more capable automation solutions. We put all the pieces together in one suite designed to make development of exceptional machines faster and easier.

High Performance Machine Control Made Easy with Kollmorgen Automation Suite

On Demand

Learn how the complete automation solution, Kollmorgen Automation Suite, can help you bring truly differentiated machines to market faster. Join our KAS training session online and simplify your development of high-performance machine control.

Online, Interactive Product Selectors

From torque, speed and power to form factor, controls and accessories—the perfect fit is key to your application’s success. Use our selection tools to choose motion products with confidence. Our instructional video shows you how simple it can be.

Electric Actuation Is Replacing Hydraulics. Are You Ready to Make the Move?

For hundreds of years, hydraulic actuation systems have been making noise, wasting energy, leaking and requiring constant maintenance — all to achieve imprecise motion over a limited range. For most of that time, they have been the only real choice for powerful actuation. But now there’s a better way. Learn the advantages of electric actuation and how to make the transition.

Easy-to-Clean, Durable Motion Systems for Food Processing and Packaging

The need to safeguard the food supply against disease-causing pathogens is absolute. But food processors and packagers struggle to keep machines sanitary while also maximizing productivity. Learn how smart component choices can enable direct washdown without damaging motors or other equipment, while leaving pathogens no place to hide.

Accelerate Humanoid Robot Development

Designing and building a humanoid robot is challenging enough. But ensuring that it is manufacturable and marketable requires a new approach to creating multi-axis motion. Get your design right from the start with these three best practices.

Adjusting Standard Motion Profiles to Optimize Operating Speed and Time

Thursday, April 18, 2024, 11 a.m. ET

The simplest and most commonly used motion profiles don’t always provide optimum results. Learn simple adjustments you can make to achieve the ideal speed and move time for your application — without the need for guesswork or extensive trial and error.

Save My Seat

Expand Machine Capability with Programmable Steppers Drives

Thursday, April 25, 2024, 11 a.m. ET

Discover the future of stepper drive setup and operation. Kollmorgen Space software simplifies programming, lowers total cost and enables new closed-loop monitoring and control capabilities. Learn how it works in this online guided tour.

AKD2G Servo Drive Update Offers More Flexibility and Protocol Focus Than Ever

Our updated AKD2G servo drive — part of our 2G Motion System — features enhancements to our existing communication protocols, adding CIP Sync functionality for Ethernet/IP and PROFINET IRT for PROFINET. The expanded offering delivers easier integration with third-party controllers, easier setup and functional safety options.

Intentional design. Streamlined setup. Ultimate performance.

The Kollmorgen 2G Motion System offers engineers the best of both worlds: A servo motor and drive system designed to work together for ultimate compatibility, ease of setup and higher performance; and the flexibility, power and control to bring any design to life—with individual components as needed.

Kollmorgen and Stereotaxis Advance the Precision and Safety of Surgical Robots

The new Genesis surgical robot is revolutionizing cardiac ablation procedures, giving patients the promise of longer, healthier lives. Learn how Kollmorgen technology and expertise made the difference for a visionary surgical robotics company.

TBM Frameless Servo Motors

TBM Series servo motors offer a direct drive, frameless design embedded directly into your machine, delivering exceptional torque and precision while eliminating backlash and maintenance issues. Find the features and options that best fit your application.

Helping You Make Extraordinary Design Possible

From factories and warehouses, to operating rooms and imaging centers, to energy production and space exploration, our motion technology and expertise enables our partners to solve the world’s toughest motion and automation challenges. Discover what we can do for your next project.

Motion for Missiles: Optimizing Performance

The electric motors that control missile fin actuators, seeker head gimbals and other mechanical systems must perform with absolute reliability. With a rapidly growing need for advanced weapon systems, learn how to specify motors that can perform reliably even in the most extreme conditions.

Frameless Performance, Made Easy

Optimize your frameless motor by simply entering your application requirements. This Interactive Performance Curve Generator does the rest, automatically.

Frameless Motors to Fit Any Application

Embedded into your machine and driving the load directly, KBM frameless servo motors deliver optimum torque density and precision in the most compact package. Browse motors that deliver continuous power up to 20.1 kW and peak torque up to 12,812 Nm in frame sizes ranging from 60 mm to 850 mm OD. Find the ideal fit for your application.

From the Factory to the Farm: Washdown Servo Motor Technology

A new era of agricultural innovation is at hand. The same high-performance, washdown-capable motors used in food, beverage and pharmaceutical production promise to transform the productivity and profitability of farming automation. Learn why.

Sizing & Selecting Servos: Understanding the Need for a System Solution

There are many parameters and variables to consider when sizing and selecting servo system components for an application. To simplify the process and maximize success, learn how to incorporate mechanical load, motion profile, ambient environment, cabling and other considerations into a system-wide approach.

Smart Technologies for Food Packaging Performance

Today’s food packagers are looking for machines that are more compact and automated, driving greater throughput and accuracy. However, it can be challenging to achieve these goals using individual components that were designed with little regard for integration. Learn a smarter approach — building machines with much of the integration built in at the component level.

Maximize Missile Performance with Advanced Frameless Motors

Tuesday, March 26, 2024, 11 a.m. ET

Missile manufacturers are under pressure to design and produce ever more sophisticated systems in greater quantities. Learn how to optimize missile guidance and control systems with a solid understanding of the frameless motor design principles that make a difference for actuator size, weight, performance and reliability. Join this informative online training.

Save My Seat

The Foundations of Electric Motion: Motion 101 Online

Wednesday, March 20, 2024, 11:00 a.m. ET

Learn the details of different motor types, open vs. closed loop control systems, and how to configure the optimum motion system for each machine axis.

Save My Seat

The Foundations of Motor Performance: Motion 101 Online

Thursday, March 21, 2024, 11:00 a.m. ET

Understand the role of feedback type and resolution as well as the influence of inertia, so you can meet your motion performance goals with confidence.

Keep Your Field Robot on the Job Longer, Working Stronger

Robot-ready motors designed for optimum size, weight and efficiency in specialized applications can extend your field robot’s operating time, range and reliability. Learn how to engineer greater success for the robots that perform difficult jobs while keeping humans safe.

Improving Food Safety and Packaging Machine Reliability

Food safety regulations are stricter. Consumers are more demanding. Competition is tighter than ever. How can you keep your food processing and packaging machines clean while minimizing washdown-related downtime and equipment failures? Learn proven methods for ensuring a safe food supply while maximizing the yield of your production line.

The Right Motor for Tough Conditions

Whether you’re designing for tough, medium or heavy washdown applications or all-weather conditions, AKMA motors offer the ideal feature set. See which AKMA motor meets your unique specifications with our streamlined selection guide.

Calculating the Total Value of Hygienic Machine Design

How do you know when designing with a high-performance servo motor that provides superior hygiene and reliable operation in demanding washdown environments is worth the investment? Learn how the patented design of our stainless steel AKMH hygienic servo motors helps improve your overall equipment effectiveness (OEE).

Powering a Submersible Robot for In-Service Inspection of Fuel Storage Tanks

Why drain a massive fuel tank so that humans can enter and inspect it, when an innovative submersible robot can do it more efficiently, more cost effectively, while keeping people and the environment safe? Learn how Square Robot used highly modified frameless motors from Kollmorgen to help make this extraordinary new technology possible.

Motion for Medical Imaging: Proven Processes, Reliable Delivery

Medical imaging systems require precise, powerful, perfectly controlled motion. Learn the proven, structured development process that can help ensure success — in the procedure room and the marketplace. Count on collaborative expertise, superior performance, dependable supply and global support.

See the Latest Addition to the P8000 Lineup

Expanding on the successful P8000 stepper drive family, the new P80360-ECE features an EtherCAT communication interface that supports cyclic synchronous position (CSP), cyclic synchronous velocity (CSV), profile position, profile velocity and various homing modes. Users can integrate the P80360 stepper drive into existing EtherCAT ecosystems — enabling real-time control for increased throughput and machine capability.

Put Your UAV on the Trajectory of Success

When the mission matters, your UAV must be designed and built to go the distance. Learn how motion solutions designed specifically for flight can minimize size and weight while maximizing torque and efficiency. Fly longer and farther with Kollmorgen.

Servo or Stepper Motor: Which Should It Be?

Servo and stepper motors are both great technologies for moving and positioning loads. But they operate in different ways, and it’s important to make the right choice for your application. Learn how these motors work, the value of each, and how to select the technology that will help your machine achieve its full potential.

We’ll Help You Design and Deliver a Better Machine

To win the future, machines, robots and automation systems need to achieve higher levels of precision and performance. Kollmorgen’s dynamic motion products, collaborative engineering expertise, and global delivery and support can help move your business to the front of the pack. Learn how we do it.

For 2024, Autorotor has improved some new accessories for rotary tables and indexing rotary tables

For turntables:

- special central hole for routing cables or pipes.

- central support, where it is possible to fix the turntable or other parts of the machine

For indexing circular tables:

- a central support, where it is possible to fix the rotating plate or other parts of the machine

- supports for the unit

Accelerating the Development of Prostheses and Exoskeletons

An innovative test-bed platform developed by Humotech delivers the torque, speed and responsiveness needed to evaluate and refine wearable designs in actual human use, accelerating the prototyping process and helping improve results. Learn how.

From the Factory to the Farm: Washdown Servo Motor Technology

High-performance motors that withstand direct washdown can dramatically increase equipment reliability and productivity. Learn the advantages that agricultural automation is borrowing from today’s factory floor.

Interactive Product Selector Tool

There’s no need to search through websites or catalogs looking for a perfect fit. Our online Product Selector tool does the research for you. Simply enter the torque, speed, power, size, and other requirements and be guided to motors, drives and cables that best suit your application.

February Training Events

Register for the live session or to receive a link to the recording

Ask The Experts Webinar: Motion Control for Food Packaging

Ask The Experts Webinar:

Motion Control for Food Packaging

Thursday, February 8, 2024, 11 a.m. ET

The need for frequent, high-pressure washdowns can reduce productivity and damage equipment. How can you clean motors directly — without the need for shields or bags, and without the risk of harmful water ingress? Get answers to your specific questions for achieving reliable motion control in hygienic food packaging environments.

Save My Seat

Simplify Regen Resistor Selection for Motion Systems

Thursday, February 22, 2024, at 11:00 a.m. ET

A regeneration resistor captures the excess electrical energy that is generated during motor deceleration. Dissipating this excess energy can prevent potential damage to your motion system. Join this online session and learn how to optimize your regen resistor for greater system reliability.

Save My Seat

Motion Innovation for Energy-Efficient Metal Forming

Learn how Kollmorgen’s newly patented technology and expertise helped the world’s #1 manufacturer of sheet-metal bending machines, Salvagnini, improve energy efficiency, performance and usability in harmony with the company’s core values.

Motion Control Fundamentals for Humanoids & Exoskeletons

Humanoid robots and exoskeletons are bringing new possibilities to healthcare, manufacturing, construction and service industries. Learn how to improve upon human capabilities with precise, powerful, efficient motion — and how to maximize commercial success.

Make Any Medical Imaging System Better

CT, MRI, hybrid, digital mammography and nuclear medical imaging. Fixed systems, mobile X-ray and ambulatory medical imaging centers. They all depend on the right motion for the right modality. Learn how to get it right.

TBM2G Motors for Simply Better Design

Design and build a more compact, efficient, higher-performing robot. TBM2G frameless servo motors are specially created to meet the unique requirements of cobot, surgical and humanoid robot joints, providing a custom-like fit while ensuring manufacturability with long-term availability and support.

Frameless Motor Performance Curve Generator

Map speed-torque curves based on variables including current, voltage, ambient temperature and winding factors. It’s easy to specify the optimum frameless motor for your application using the online Performance Curve Generator.

On-Demand Webinar: Optimizing Form Factor With the D2L Rule

The length and diameter of your motor have dramatic effects on stabilized platform performance. Learn how to apply this rule to size the most compact motor.

We’ll Help You Design and Deliver a Better Machine

To win the future, machines, robots and automation systems need to achieve higher levels of precision and performance. Kollmorgen’s dynamic motion products, collaborative engineering expertise, and global delivery and support can help move your business to the front of the pack. Learn how we do it.

Humanoid Robots: From Design to Delivery

In any engineering project, time and budget constraints at the prototype stage can lead to excess costs and delays when scaling up to full production. Learn how to design for both performance and manufacturability, beginning with the prototyping stage, to accelerate your time to market and maximize your prospects of success.

The Difference Between Continuous Ratings and Holding Continuous Loads

When a motion application requires holding a load in position for an extended time period, engineers encounter a lot of confusion around words like “stall” and a lot of uncertainty about proper servo motor sizing. Get clear answers and practical advice to ensure the success of your application.

Preventing Electromagnetic Interference in Servo Cables

Available On-Demand

Power cables can cause electromagnetic interference that corrupts the position and velocity signals carried by nearby feedback cables. Learn how to tame EMI and ensure predictable servo motion.

Efficient and Effective Risk Management for Vertical Axes

With new safety standards that require periodic brake testing and prohibit embedding of test functions within standard controls, what’s the best way to keep operators safe, maximize productivity, and simplify machine design? Learn the advantages of on-drive safety functions.

AKM2G Servo Motors

Get significantly more torque, increased feedback performance, reduced cabling and other next-generation capabilities—without changing your installation footprint. What will these motors do for your machine?

Size Your Motor and Drive in Minutes

Keep it simple. If you know your application requirements, the Motioneering tool will guide you to the motor and drive pairings that best fit your needs.

Improving the Precision and Productivity of Lithium-Ion Battery Coaters

Through the rapid growth of electric vehicles and other battery-powered products, lithium-ion batteries are changing the world. Battery manufacturers are under intense pressure to increase quality and yield. Learn how a battery pole-coating machine achieves micron-scale accuracy and 33% higher throughput.

Compact Joint Design for the Next Generation of Surgical Robots

In robot-assisted procedures, surgeons value the ability to place multiple instruments in a nearly parallel orientation. Learn how to design compact robotic arm joints that give surgeons the dexterity they need and help improve patient outcomes.

5 Easy Steps to Better EO/IR Motion

A successful EO/IR program depends on efficient prototyping, cost-effective production and reliable supply. Don't let customization problems derail your project. We'll show you how to get exactly what you need in a standard or easily modified motor.

Your Agricultural Robot Can Be More Productive

New agricultural robots can perform almost any task human hands can do — but much faster, working night and day without rest. Learn the motion technologies and choices that can help your robot reach its full potential for productivity and profitability.

Tips for Selecting a Stepper Motor On Demand

With the wide range of stepper motor options, how do you select the right motor for your application? In this session, Kollmorgen experts cover the key differentiators in stepper motor technology and help you choose the best options for your application.

Watch Now

How to use grounding, shielding, and Bonding to Reduce

Electromagnetic Interference (EMI)

On request

Mitigation of electromagnetic interference is essential to maintain accurate movement without surprises. Find out why shielded cables are important, how to ground cables properly, and how to verify that your grounding is working properly.

Watch now

Motion control sizing and programming tips for gantry applications

On request

Because you need to synchronize movement across multiple axes, designing and implementing a portal application can be particularly challenging. Learn special considerations, product sizing methods, and motion programming techniques that guarantee success.

Watch now

Like a customizable Cobot design It can help you build success Society of Surgical Robotics

On request

Join Dr. Jindong Tan, President and Founder of Azure Medical Innovation, along with Gene Matthews, Senior Product Manager, Kollmorgen, as they discuss navigating the unique challenges presented in the surgical collaborative robotics market. They will explore critical technical aspects in specifying the needs of surgical applications regarding collaboration features, integration of AI into the surgical flow, and certification requirements.

Watch now

Differentiating braking techniques for your servo system

On request

Correct braking by servomotor is essential for the safety of employees while maintaining production requirements. But how do you choose which braking technique is right for your application? This session explores applications for safe, dynamic and safe dynamic braking.

Watch now

Discover Compact Motors with Big Performance

Frameless motors allow you to design a lighter, more compact machine with the precision of direct drive. Directly embedded in your machine’s own housing, they’re ideal for reliable performance in the most rigorous environments. Explore the possibilities.

Implementing and Installing Frameless Motors

With frameless motors integrated directly into the mechanical structure, your machine can be more compact, efficient and dynamic. In this on-demand webinar, Kollmorgen specialist Tom S. Wood shows you how to solve the most common design challenges.

Frameless Performance, Made Easy

Optimize your frameless motor by simply entering your application requirements. This Interactive Performance Curve Generator does the rest, automatically.

Kollmorgen and Stereotaxis Advance the Precision and Safety of Surgical Robots

A pioneer in surgical robotics envisioned a new paradigm for performing more precise and effective cardiac ablations, but success would require advanced motion capabilities and collaborative engineering expertise. Learn how Kollmorgen helped bring the Genesis surgical robot to life.

It’s Time to Consider the AKM Servo Motor

The AKM series of servo motors has always been a top performing motor for our customers. Now with improved lead times as short as 2 weeks on some motors, it’s time to give us a call to see if we can help with your machine design too.

Stop, Hold and Go Safely: Motion Tuning for Vertical Loads

Gravity never compromises. When vertical load safety matters, neither should you. Learn how to tune your vertical axis right the first time and ensure reliable operation every time with this helpful guide covering braking physics, safe brake control, safe brake testing and more.

Stop Dynamic Loads with Confidence

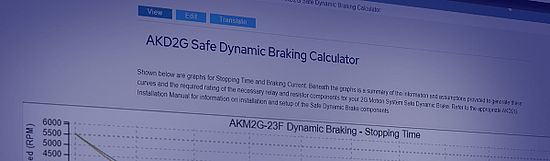

Learn how the AKD2G servo drive Safe Dynamic Brake Calculator can help you properly size your system without the need to repeatedly buy and test components. Speed development time and save money while ensuring accurate, timely braking.

Efficient and Effective Risk Management for Vertical Axes

With new safety standards that require periodic brake testing and prohibit embedding of test functions within standard controls, what’s the best way to keep operators safe, maximize productivity, and simplify machine design? Learn the advantages of on-drive safety functions.

Machine Safety: The New Era of Protection and Productivity

Learn the evolution of machine safety—from cages and disrupted production to light curtains and continuous production. Now you can eliminate shutdowns without putting operators at risk.

The best integrated motors in the world

World's most compact integrated 4.5 kW

servo motor - 13.5 kW peak

Controller, PLC, encoder, power supply, industrial Ethernet and built-in switch integrated in one unit

SPS - Smart Production Solutions | Hall 4 Booth 301 | Nuremberg, 14.-16. November 2023

Contact JVL for a free e-ticket

Get your free ticket now, simply by contacting JVL. We will then send you a ticket code.

It is a great opportunity to meet JVL and discuss your application and requirements.

Book a meeting with JVL

ServoStepTM in size NEMA34 keeps expanding

Large variety of shaft versions: Ø9.53 mm, Ø14.0 mm, double shaft, hollow shaft and now also Ø12.7 mm.

Market leading resolution of 409600 counts/rev

Optional Ethernet protocols and possibility to daisy-chain Ethernet cables from motor to motor.

High power positioning in a small all-in-one package

The new integrated servo motor MAC083 offers 83 W / 4000RPM at 24VDC and 250W peak.

This makes it the most powerful integrated motor in the NEMA23, length 110 mm.

Optional with absolute multiturn encoder based on the Wiegand principle where no battery is needed.

Power Supply Optimizer

New combined power dump and 24VDC control power supply.

Has your power supply shut down during braking?

Braking produces problematic return energy.

The new power supply optimizer is designed to address this problem, by adding a built-in power dump circuit to the power cable.

It greatly improves protection of both the motor and the power supply.

- Built-in 24 VDC control power supply for CVI when using 48-72 VDC.

- Adapts automatically to the voltage level.

- Easy plug-n-play, no settings needed

320 W Stainless Steel Servo IP69K

MAC231 - All-in-one Integrated servo motor in stainless steel and IP69K. Ideal for harsh environments.

Protected against both high pressure and high temperature washdowns.

320 W RMS power S3 with 25% duty cycle and 750 W peak. 50 Nm with optional built-in gearbox.

IO-Link

JVL can now also connect to IO-Link via our new IO-Link Gateway which can be used on both our MAC motor® integrated servo motors and ServoStepTMintegrated stepper motors.

IO-Link is a cost effective alternative to industrial Ethernet.

For ServoStepTM you can additionally run 2-5 motors on 1 pcs IO-Link Gateway using multidrop, reducing cost even more.

ServoStepTM range

JVL supplies integrated stepper motors with closed-loop, ePLCTM, multiturn encoder and Ethernet inside.

NEMA17-43 (0.18-25Nm)

Read more about all the options in the flyer

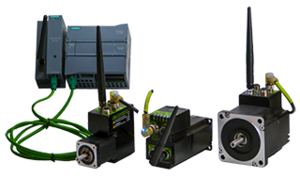

Industrial Wireless Ethernet

Supporting both EtherNet/IP, Profinet and ModbusTCP/UDP, JVL can now deliver wireless Ethernet for the whole range of ServoStep motors, NEMA17-43.

Set up your motors as Client or Access Point, using 2.4 GHz or 5 GHz.

To avoid cabling, use a battery for motor power. Combined with the closed-loop feature an energy saving of 93% can be reached.

Quick power connection guide for MIS17-43

In just 3 minutes you get all the important information about how to connect JVL's ServoStepTM motors NEMA17-43.

You learn the basic specifications, color coding and about pitfalls to avoid.

New shafts for direct mount

NEMA23 motors are now available with hollow shaft or oversized shaft. Both motor types have large double row ball bearings so you can directly mount a spindle or timing belt wheel. No coupling needed.

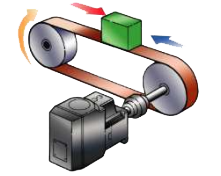

MotorSizer 4.0 sizing tool

With the free JVL software MotorSizer you can calculate and show the combinations of motors and gears that can run the application according to your specifications.

Possible types of drive set-ups include:

- A belt driven application

- A ball screw application

- A rotary disc application

MAC motor® range

JVL supplies integrated servo motors with ePLCTM, brake, multiturn encoder and support for all Ethernet protocols.

50-4500 Watt.

Read more about all the options in the flyer.

Motor for direct mount of a timing-belt wheel

The new MIS23xx49 ServoStepTM motor features a large Ø14 shaft and double row ball bearing.

The oversized bearing allows high radial forces directly on the motor shaft - up to 5100 N.

This combination can shorten your overall design length and save you the cost of an additional bearing housing.

The ServoStepTM motor is an all-in-one unit with embedded ePLCTM and 2 port Ethernet switch.

eVTOL Motion, From Design to Delivery

Did you ever imagine you could take an air taxi from the airport to a downtown location? Or see road congestion give way to direct, point-to-point delivery of goods overhead? With innovative eVTOL technology, all this and more could come true sooner than you thought. Learn how Kollmorgen is helping.

The Right Motor For Tough Conditions

From its anodized aluminum coating to a vented design ideal for medium and heavy washdown applications, lightweight AKMA motors offer reliable performance when directly exposed to harsh environments. Use this guide to ensure the optimum AKMA fit and performance for your application.

Increasing Trajectory Welding Speed in Lithium-Ion Battery Production

A critical stage in producing the lithium-ion batteries used in electric vehicles is seal-welding the top cap to the shell. Learn how the precision of direct drive technology allows laser welders to perform this micron-scale task significantly faster while improving control accuracy by 30% and achieving a yield rate over 99%.

Motion Control Fundamentals for Humanoids & Exoskeletons

Tuesday, November 14, 2023, 11:00 a.m. ET

Design and build better humanoid robots and exoskeletons. Learn how to choose motion systems with the power, precision and efficiency to improve upon human capabilities, and to cost-effectively take your design from prototype to commercial production.

Save My Seat

AKD2G Quick Setup

Wednesday, November 15, 2023, 11:00 a.m. ET

Learn how to use AKD2G Workbench software to set up your drive to perform next-generation motion tasks—quickly, confidently, productively.

Save My Seat

Advanced Configuration for AKD2G Dual-Axis

Thursday, November 16, 2023, 11:00 a.m. ET

Take full advantage of the dual-axis drive capabilities. Learn how to control two axes with one drive, including triggering inputs, tuning, troubleshooting and data capture.

Moog and Salvagnini: A Decentralized Control Architecture Adapted to Metalworking Applications

Moog Inc. (NYSE: MOG.A E MOG.B), a leading provider of high-performance drive technology solutions, and Salvagnini, also a leader in innovative solutions for the automation of metalworking applications, have jointly developed an 8-axis Cartesian handling robot for automatic guidance and sorting of punched or sheared parts designed and developed in machining centers.

Many metal processing companies face a variety of challenges, including high batch variability, smaller and diversified batches with special applications, and customer demands for shorter lead times and quality guarantees. Although the plant's systems and production lines are already designed to be flexible enough, current requirements often contradict this. Another option to meet customers' fast and diverse production needs is the Salvagnini 8-axis Cartesian manipulator. It fits into the existing concept of the room, fulfills various tasks and consumes less energy than comparable solutions on the market.

As Moog offers electric, hydraulic and hybrid solutions for machine development, Moog and Salvagnini were able to take a technology neutral approach. Moog engineers evaluated a range of technologies and selected the most appropriate solution for Salvagnini Cartesian Manipulator and Metalworking customers.

The Moog development team integrated its electromechanical solutions into the design of the Salvagnini robot so that the system is able to link different processes, including the transportation of the current workpiece from one station to another. To develop the multi-axis solution, Salvagnini engineers chose a DE2020 power control module, a DI2020 motor with integrated electronics, a DR2020 decentralized single-axis drive and HD/FAS H servo motors from Moog.

"In the arrangement of complex systems, it is difficult and not always possible to find space for a switchboard. "It is therefore very important to reduce the volume of the control box," explains Stefano Bizzotto, motion control manager at Salvagnini. “Ideally, the control box should disappear or be completely integrated into the floor plan of the machine. That's why we decided on decentralized drives and motors with integrated electronics."

By choosing electromechanical technology, we were able to design integrated plug-and-play systems that can communicate perfectly even with equipment from other manufacturers," adds Massimo Daziale, Moog's sales manager. “Simplified installation allowed for faster service. Other benefits include the smaller dimensions and lower weight of the machine's moving parts, resulting in greater acceleration and speed, as well as the ability to integrate new functions in the same space."

Together, Moog and Salvagnini upgrade existing machines to replace existing components or integrate new components. Modernizations are considered necessary because improving technological standards increases production efficiency while reducing operating costs. The intensive design and construction collaboration between the development teams of both companies is leading machine tool users to the next generation of increasingly connected systems focused on sustainability and Industry 4.0 readiness.

Moog is able to design the most appropriate combination of technologies and solutions to meet individual customer needs in these areas.

Optimize Form and Fit with Our 3D CAD Product Models

Search, configure and visualize more than 50,000 motion product models on demand. Then download 3D models in CAD for direct incorporation into your design.

Watch the Video

Direct Drive Helps Improve the Production Speed and Quality of Electric Vehicle Batteries

Blade batteries have become the most popular choice for electric vehicles due to higher safety performance, longer cruising range and faster charging speed. Learn how Kollmorgen helped a manufacturer of blade-battery production equipment significantly improve throughput and quality to meet the rapidly growing demand.

Minimize Weight and Size to Maximize Efficiency

By specifying lighter, more compact, higher-efficiency motors, you can achieve optimum performance for positioning UAV flight-control surfaces, visualization systems, sensors, payloads and more. Learn how to design a more capable aircraft, bring it to market faster, and support it confidently throughout its lifecycle.

Correct Servo Motor Sizing for Continuously Holding Loads

The word “stall” can mean very different things in different contexts. Be sure you’re applying it correctly when sizing AC servo motors that must continuously hold a load. Our white paper clarifies the technical issues and provides motor selection advice you can use, so you can be sure of safe, reliable operation.

Developing a High-Slice, High-Res CT Scanner: A Cross-Functional View

For any project involving high-performance motion, there are many stakeholders beyond the engineering team. Learn best practices for bringing together a successful cross-functional team focused on delivering innovative medical imaging machine designs.

Robot Ready: An Industry First

Get the highest torque density, at the speeds you require, in a robot-optimized form factor, with minimal temperature rise. TBM2G means no more tradeoffs.

Deliver High Performance in a Compact Form with TBM2G Frameless Motors

With significantly higher torque density in a more compact axial design, next-generation TBM2G frameless motors are ready to perform, ready to fit your design, and ready to scale. Learn how you can engineer a more capable machine, without compromise.

Get the Brochure

Get Higher Performance in Less Space with AKM2G Servo Motors

Next-generation AKM2G servo motors provide substantial performance improvement without changing the motor mounting or consuming more machine space. And they’re available with a wide range of options including extensive feedback, shaft, connector and support for functional safety.

Explore Now

Drive More Powerful Motion Solutions with AKD2G Servo Drive

Integrated SafeMotionTM functions. Unparalleled connectivity. Higher power density. Simpler usability. Next-generation AKD2G drives put you in control to design more ambitious machines with more capable performance and more confident engineering. Learn more.

Get the Brochure

Accelerate Development, Increase Throughput and Maximize OEE with Kollmorgen Automation Suite™

With controllers, drives, motors, communications and programming tools designed to work together, you can engineer more capable automation solutions. We put all the pieces together in one suite designed to make development of exceptional machines faster and easier.

Explore KAS

October Training Events

Register for the live session or to receive a link to the recording

Choose the Right Motor to Extend UAS Flight Time and Distance

Wednesday, October 25, 2023, 11:00 a.m. ET

From saving lives to delivering goods, unmanned aerial systems help military, police, humanitarian and commercial organizations complete difficult missions efficiently and safely. Learn how to create motion systems optimized to help extend UAS flight time and range.

Save My Seat

The Gravity of the Situation: Vertical Load Handling for Automation

Thursday, October 26, 2023, 11:00 a.m. ET

When gravity is a factor in managing servo loads, you need to take special care in sizing the motion system, handling faults, ensuring employee safety and more. Join the experts as they walk you through best practices in a real-world application.

How to Set Up Your AKD for Success

Wednesday, October 18, 2023, 11:00 a.m. ET

New to setting up a servo drive? Already experienced but looking for tips for a more effective setup process? This session is for you! Follow along and learn how to minimize setup time, apply best practices, and create precise motion—step by step.

Save My Seat

Advanced Motion with AKD

Thursday, October 19, 2023, 11:00 a.m. ET

Create intricate motion tasks, identify mechanical compliance, and increase performance by mastering the programming and diagnostic tools built into the AKD.

Clean Mirrors for Clean Energy

To keep energy flowing, heliostat solar plants need to keep thousands of massive mirrors clean. Learn how Kollmorgen motion helps increase maintenance efficiency by 500% and cleaning efficiency by 2,400% while operating in unpredictable terrain at temperatures often below –30ºC.

Learn how evolving principles of inertia matching affect your machine design

The old principles of inertia matching between load and motor are changing. Control algorithms are more advanced and processors are faster than ever. Whether you’re updating an existing machine or starting from scratch, get the best performance possible with help from Kollmorgen’s team of engineers. This whitepaper can get you started.

See Exactly How Your Motor Will Perform

With just a few clicks, our Performance Curve Generator graphs the continuous torque, peak torque at different temperatures, and torque/speed characteristics of all our housed motors. There’s never been an easier way to evaluate the optimum motor for your application environment.

The New P80360 Stepper Drive

The feature-rich P80360 stepper drive offers closed-loop positioning, full programmability using an intuitive GUI, and faster setup with Kollmorgen motors. It’s ideal for point-to-point movements as well as linked motion sequences in a wide range of applications. Learn all the benefits and specifications.

Get the Features, Benefits and Specs of Kollmorgen’s Newest Drive

Now you can achieve near servo-like smoothness and precision with minimal risk of undershoot or overshoot even in compliant applications or when moving heavy loads. Get all the benefits and technical details of the fully programmable P80360 stepper drive with closed-loop position control.

Discover the Power of Kollmorgen Automation Suite™

From complete manufacturing lines to small, automated desktop machines, the Kollmorgen Automation Suite (KAS) delivers a small yet powerful and cost-effective hardware platform ideally suited for modular or stand-alone machines that want the maximum in flexibility and performance.

From the Factory to the Farm: Washdown Servo Motor Technology

A new era of agricultural innovation is at hand. The same high-performance, washdown-capable motors used in food, beverage and pharmaceutical production promise to transform the productivity and profitability of farming automation. Learn why.

How Can You Design a More Capable Surgical Robot?

Surgeons value the ability to place instruments as closely together as possible when performing minimally invasive procedures. Learn how to design axially compact, high-torque robotic arm joints that help surgeons deliver better outcomes.

Providing You Engineering Expertise

With decades of engineering experience in motion systems, we have a great base of knowledge to share. From white papers to blogs and free training, we are continually updating our content to keep you informed. Featured below is some of our most popular content.

Essentials of Motion Control

Register now and Learn at your convenience

The Essentials of Motion Control self-paced class, allows you to follow the path from electrical energy to physical motion, focusing on every opportunity to optimize motor efficiency and performance. Ready to get moving?

Get Started Now

Stepper Motor or Servo Motor: What are the key factors to consider?

Stepper or servo? It’s one of the most common and important questions in motion engineering. And that’s why we’ve provided answers you can use in one of our most popular white papers ever. Read it, and make the right choice with confidence.

Get the White Paper

Three Design Considerations that Indicate a Machine Needs a Frameless Motor

Does your machine need to operate in a smaller footprint, deliver enhanced performance or endure extreme conditions? Learn why a frameless direct-drive motor is likely your best solution.

Read the Blog

Still Designing to Decades-Old Inertia Matching Rules?

Machine Designers have pursued the idealized 1:1 inertia matching for the motor and load. But what if this rule no longer applied and you could use a significantly smaller motor and still achieve perfect motion? You can, and here’s how.

Get the White Paper

High Performance Machine Control Made Easy with Kollmorgen Automation Suite

Tuesday, September 12, 2023, 11:00 a.m. ET

Kollmorgen Automation Suite delivers what you need to develop high-performance motion axes and bring your machine to market faster. Learn how to use the programmable motion controller and integrated development environment in this informative online training session.

Save My Seat

The Foundations of Electric Motion Motion 101 Online

Wednesday, September 20, 2023, 11:00 a.m. ET