SUCO Robert Scheuffele GmbH & Co.

BIBUS SK, s.r.o. has been supplying its customers for years with SUCO Robert Scheuffele GmbH & Co., a leading global manufacturer. KG.

From pressure switches, switches to pressure sensing, we offer a complete range of products from this renowned German manufacturer.

BIBUS SK, s.r.o. is an exclusive distributor for SUCO - Robert Scheuffele GmbH

At the recently held International Sales and Marketing-Meeting of SUCO - Robert Scheuffele GmbH, our company BIBUS SK, s.r.o. awarded a prestigious award for 25 years of successful mutual cooperation. As SUCO exclusivedistributors, we are rightly proud of this award. At the same time, we are looking forward to further years of successful cooperation with SUCO - Robert Scheuffele GmbH, as a world leader in the field of pressure monitoring.

Source:

International Sales and Marketing-Meeting of SUCO - Robert Scheuffele GmbH

Catalog sheet:

www.suco.de

CATALOGUE RELEASE 2021

SUCO product overview flyer

SUCO/ESI pressure switches and sensors for hydrogen applications

SUCO - Robert Scheuffele GmbH offers a range of compact and robust pressure switches (NO, NC, CO) suitable for applications using hydrogen, with a variable pressure range of 0.1 - 400 bar, which are made of stainless steel SAE 316L. There are models with different threads and also a variant with an installed cable.

Silicon on Sapphire (SOS) pressure sensors are ideal for hydrogen applications.

The technology of the sensing element is based on a thin sapphire plate of monocrystalline structure, on which a Wheatstone bridge of silicon is created by the epitaxial method. The latter is characterized by excellent mechanical and thermally stable properties and minimizes unwanted parasitic effects, which has a positive impact on accuracy and stability. In connection with the titanium membrane, a unique interplay is created, which enables high temperature and long-term stability.

These hydrogen switches must meet strict requirements to be hydrogen resistant and also reliable and accurate. In our SUCO program, we offer special mechanical switches for hydrogen.

The GS4200H sensor is an excellent example of a Silicon on Sapphire (SOS) pressure sensor ideal for hydrogen applications. This sensor is designed to withstand the high pressure and reactivity of hydrogen, which guarantees reliable measurement of hydrogen pressure changes and efficient use of hydrogen as an alternative energy source.

Mechanical pressure switches

H164 (key size 24)

- opening contact (NC), closing contact (NO)

- 0.1 – 50 bar

- safety against overpressure up to 600 bar

- membrane made of EPDM, casing made of stainless steel SAE 316L

- cCSAus certificate (in process)

H186 (key size 27)

- changeover contact (CO)

- 0.5 – 200 bar

- safety against overpressure up to 700 bar

- membrane made of EPDM, casing made of stainless steel SAE 316L

- cCSAus certificate (in process)

H183 (key size 27)

- changeover contact (CO)

- 100 – 400 bar

- safety against overpressure up to 600 bar

- membrane made of EPDM, casing made of stainless steel SAE 316L

- cCSAus certificate (in process)

H344 / H345 (key size 27)

- changeover contact (CO)

- 0.3 – 150 bar

- safety against overpressure up to 300/600 bar

- membrane made of EPDM, casing made of stainless steel SAE 316L

- ATEX / IECEx certificate (M1)

Pressure transducers and sensors

ESI Technology of Wales has developed a broad product portfolio of high quality pressure transducers and sensors for standard and special applications with a pressure range of up to 5000 bar to meet the growing demand for products suitable for use with H2, particularly in the oil and gas, marine and subsea industries. applications.

GS42000H

- 0 to 1500 bar

- protection against overpressure – 4 times the value

- titanium alloy pressure sensor, SoS

- optional ATEX and DNV-GL certificate

- high resistance to corrosion

GD4200HUSB

- -1 to 5000 bar

- protection against overpressure – 2 times the value

- titanium alloy pressure sensor, SoS

- ESI-USB software with a sampling frequency of 1000 Hz

- maximum resolution and accuracy of ± 0.15% BFSL

HP1000H

- 0 to 5000 bar

- protection against overpressure – 1.5 times the value

- titanium alloy pressure sensor, SoS

- optional ATEX and DNV-GL certificate

- high resistance to pressure peaks

HI2000H

- 0 to 1500 bar

- protection against overpressure – 4 times the value

- titanium alloy pressure sensor, SoS

- optional ATEX / IECEx certificate

- resistance to very high temperatures

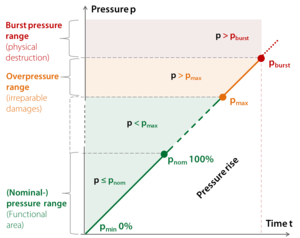

SUCO extends the overpressure protection and redefines the burst pressure of its mechanical pressure switches

SUCO pressure switches "Made in Germany" are represented in nearly every industrial sector, in which hydraulic or pneumatic pressure must be reliably and safely measured, monitored and controlled. For decades, mechanical pressure switches from SUCO have acquired an excellent reputation worldwide. Its customers include well-known manufacturers in the fields of mobile hydraulics, machine and plant construction, as well as medical and process technology.

In addition to the wide range of variants and the defined temperature resistance covering extreme conditions (NBR down to -40°C, FFKM up to +120°C), the extraordinary features of SUCO’s mechanical pressure switches also include long service life and outstanding overpressure safety.

By continuously optimizing its processes and components, SUCO has succeeded in significantly increasing the already above-average overpressure resistance of its mechanical pressure switches. This was confirmed, among other things, by an external, independent test laboratory as part of a dynamic pressure change test.

A selection of mechanical diaphragm and piston pressure switches has been tested. Based on the test results, the above average overpressure resistance values of all tested pressure switches can be confirmed. Some of the series completed the entire test scenario with a total of 1.5 million cycles at various pressure levels up to max. 720 bar without failure.

Following the results, SUCO will extend the values for static overpressure strength even further. In addition, SUCO will specify values for the static burst pressure for the hex 24 and hex 27 mechanical pressure switches in future, which will reach impressive values of up to 1,000 bars.

The average burst pressure within the fluid market is approx. 20-30 % higher than the overpressure safety. With burst pressure values of up to 1.75 times the overpressure safety, SUCO switches are significantly higher, which has a positive effect on the service life and operational safety.

Thanks to this improvement, the SUCO group is taking one big step towards its vision of being one of the leading solution providers in the field of pressure monitoring and drive technology. Together with more than 65 mostly exclusive sales partners, worldwide customer service is ensured.

The SUCO group - a reliable and innovative solution provider, worldwide at your side.