ZF Single-disc - single-disc brakes and clutches

What can single disc - single disc brakes and clutches provide?

Thanks to their technical advantages, simple setup and suitable external dimensions, electromagnetically controlled single disc clutches and brakes are increasingly used to automate mechanical work processes. Their use ranges from the drive circuits of systems with uneven loads to the precise control of duty cycles with a high shift frequency.

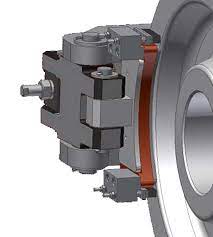

Wheel brake WBHS

WBHS wheel brakes are parking and safety devices that can be used as dynamic brakes in an emergency.

WBHS wheel brakes are applied by force generated by springs on both sides of the crane wheels. Oversized brake shoes with bonded friction material are applied to the side flanges of the idler wheels, providing frictional forces and thus braking capacity.

Designed as parking brakes to be used when the equipment comes to a complete stop, WBHS wheel brakes can also be used as dynamic brakes in an emergency. By applying spring force directly to the wheel surrounds, they minimize the stress and strain otherwise experienced by sleeper beams and crane load assemblies.

TECHNICAL SPECIFICATIONS

Braking force: 50 KN to 120 KN

PROPERTIES

- Flow control valve installed on the brake for a controlled setting time of 3 to 30 seconds

- Self-lubricating stainless steel bushings and pins on all pivot points

- Contactless switch for release signaling

- The brake shoes can be easily removed and replaced

- Made of high quality structural steel

- Nominal inserted clearance 1 mm per side

- Recommended maximum distance of 2 mm per side

- Comes with a release nut for mechanical brake release

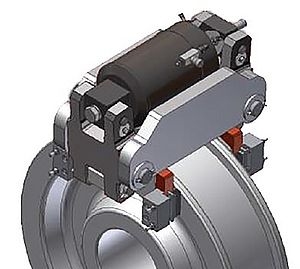

Electro-magetic brake 3CA2

3CA2 brakes from STROMAG are safety brakes with spring pressure and electromagnetic release by brake release. They are equipped with automatic pad wear compensation, which ensures constant torque regardless of pad wear.

CA2 disc brakes were originally designed to meet the toughest conditions of heavy-duty steel cranes, ensuring safety and reliability in dynamic braking. Today, these brakes respond to the limitations of high-performance braking regardless of the application or conditions.

TECHNICAL SPECIFICATIONS:

- Braking torque: 1600 - 3350 Nm

- Maximum speed: 50 m/s

- Diameter: 445 - 795 mm

FEATURES:

- Electromagnetic safety disc brake

- Spring braking

- Electromagnetic release

- Automatic lining wear compensation

- Brake pads with wear indicator

- Switch to verify opening

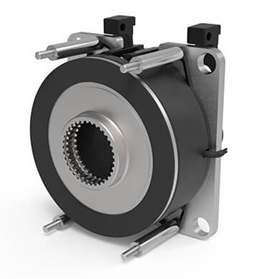

QuietLift brake

DESCRIPTION:

The QuietLift brake is an electromagnetic spring-loaded brake that works for static and emergency braking.

This solution, designed to offer a double braking system, is particularly suitable for gearless motors to comply with EN81 - 20/50:2020 lift standards.

Equipped with a Warner Electric Sensor (WES), the QuietLift brake ensures reliable detection and wear monitoring. Equipped with an innovative low-noise system constructed from steel, this brake ensures optimal performance throughout its lifetime. In addition, the brake is designed to accommodate modular mounting positions and sizes according to your project requirements.

Additional modifications for your projects are available upon request.

Properties:

- Compact design

- Torque 125 - 700 Nm

- Redundant braking circuits

- One voltage as standard

- WES: Contactless sensor detection

- Quiet operation <60 dB(A) (patented)

- Modular fixation (easy PCD setup)

- Duty cycle: 50% under voltage

At Warner Electric, we've been helping electrify the powertrain for decades with our electromagnetic brakes. Let's build together!

As one of the largest manufacturers of industrial brakes in the world, we know your customers and we know electrification.

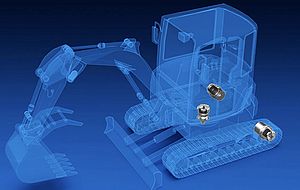

Warner electric parking and emergency brakes are proven, reliable and clean alternatives to hydraulic and pneumatic brakes. Our technologies have been used for decades to electrify OEM vehicles such as forklifts, golf carts and work platforms. They are ideal for battery-powered applications in compact construction equipment, outdoor power equipment, autonomous agricultural equipment, AGVs and more.

Warner Electric: Your Powertrain Electrification Partner We actively work with powertrain manufacturers and OEMs to cost-effectively integrate electric brakes into their lineups to reduce maintenance and improve the performance of their customers' vehicles.

Our electric brakes are:

- Durable, field-tested and maintenance-free

- Ecological with low energy consumption and compact design

- Easily integrates into existing designs

- Accurate and powerful

- Available as custom and standard

- Warner AVG applications

Not sure what type of electromagnetic braking solution you need?

Ask a Warner Electric Electrification Specialist

We'll help you customize the solution that best suits your powertrain needs, right down to brake size and IP rating.

Find out more about our offering on our newly launched Powertrain Electrification website.

Contact us today to find out how our electrification expertise, global manufacturing footprint and production line flexibility can help you realize faster project turnarounds and lower material costs.

Contact a Warner Electric electrification specialist today

Innovative energy-efficient Warner Electric brakes help OEMs increase electric equipment run time

The off-highway industry is currently moving through a significant transition. The journey started about 10-12 years ago as the forklift truck industry began converting from internal combustion engines into electric drives. Today, construction equipment, more precisely, compact construction equipment, has also begun the transformative conversion to electric drives.

As with the automotive industry, national and municipal emission regulations are rapidly becoming more restrictive for off-highway vehicles and equipment. In some areas, the use of gas-powered equipment has already been completely banned. Some analysts believe that by 2030, 50% of the construction equipment market will be electric powered.

As environmental awareness grows, construction equipment manufacturers have begun to respond with electric powered equipment that meets various mandated emission regulations. However, they are also being driven by voluntary environmental policies adopted by construction contractors and large equipment rental companies.

This new generation of much quieter equipment is not only environmentally friendly, but also provides increased operator comfort, health and safety benefits.

Warner Electric offers innovative braking solutions designed to reduce power consumption on a wide variety of battery-powered construction equipment, including slewing and track drives on excavators, wheel and track motors on compact track loaders, skid steers, wheeled excavators, compact dunpers and mobile elevating work platforms (MEWPs).

Highly experienced Warner Electric application engineers routinely work with Tier 1 drivetrain OEMs as well as major construction equipment manufacturer engineering teams to develop compact, energy efficient braking solutions to meet the needs of each vehicle requirement, whether it’s for a completely new design or the electric conversion of existing equipment.

Our design process typically starts with one of our existing industry-proven braking solutions, including the popular PK and CBTB ranges. Once selected, customization of the unit begins, including IP rating, manual release cables, connectors, sensors and friction material. The result is a “plug and play” product that the OEM can easily integrate into his drivetrain.

Warner Electric’s market-leading PK (Very Thin) brake is the industry’s original compact, proven brake design. These pre-assembled on/off dry safety brakes are used for parking and offer emergency stop capabilities. The vehicle’s AC motor is used in combination with the PK brake for regenerative braking of the vehicle.

The benefits of this cost competitive range include one-piece design for easy assembly, lower power consumption, longer battery life, and overall lower maintenance costs. These brakes are enclosed to withstand harsh outdoor environments. IP67-Rated models are available to meet challenging washdown application requirements.

New PK brake designed for quieter operation

The recently launched PK- Low Noise Design brake features a unique patent-pending dampening system that significantly reduces operating (engagement) noise to below 70db. The new brake was developed for applications where high noise levels can be annoying such as under-cab slewing drives on mini excavators.

High-torque, high-speed CBTB brakes for dual-drive E-vehicles

The CBTB family of electromagnetic axle brakes are specifically for use on battery-powered, dual-drive vehicles with capacities generally up to 8 tons (17,900 lbs.). These advanced high-speed, high-torque brakes provide reliable emergency and parking brake functionality and allow for increased maximum vehicle speed and improved productivity.

Proprietary W134 non-stick dry friction material, designed and manufactured in-house, is available on PK and CBTB models for increased high-capacity braking requirements at very high speeds. The linear speed of the friction material determines the speed limit, certain brakes and design sizes have been functionally tested at speeds of 12,000 rpm.