Warner Electric is expanding its range of electric vehicles with a new bi-stable brake

Warner Electric, a leading brand of Altra Industrial Motion Corp., has developed a new electromagnetic brake that significantly reduces energy consumption during operation. The SSPB pulse brake is highly efficient and well suited for electric applications - it increases reach and effectively regulates soft braking. Energy saving is an important consideration in most applications, but nothing more than in the electric vehicle market. OEMs are struggling to maximize the efficient range of electric vehicles in order to gain an operational and market advantage. Increasing efficiency and reducing the number of visits to the charging point are paramount. The longer the range, the more productive, practical and cost-effective it is. With limited battery work, it is necessary to focus on reducing energy consumption in vehicle support systems in order to further improve the reach of vehicles. Warner Electric has used its extensive experience as a global manufacturer of electromagnetic brakes to provide an efficient braking solution that meets these requirements. The SSPB is designed to maintain battery life through reduced power consumption. This stable brake relies on current pulses to operate the brake, which offers a significant advantage over other devices. Electromagnetic brakes usually require the maintenance of a constant power supply, so the brake consumes energy whenever it does not control the stop. The SSPB reduces this energy consumption by relying on the opening or closing of a single short current pulse, thus eliminating the need for a constant power supply. One pulse will be sent to close the brake and stop, another to open them and start moving. As a result of this efficiency, the final amount of stored energy of the vehicle can be used for other functions. This can significantly increase the scale, improve the viability of electric vehicles in many new industries or environments. Energy savings benefit both purely electric vehicles and hybrid electric systems.

The SSPB brake is specially designed to work as a turnkey solution. A built-in controller is standard with Warner Electric's focus on ease of use during installation and operation. Warner Electric works directly with OEMs to optimize equipment to suit existing or new vehicle platforms, ensuring that SSPBs can be retrofitted or incorporated as part of new vehicle designs.

Improving the environmental performance of electric vehicles is not limited to choosing a more sustainable energy source. By reducing the power consumption of the brake system by specifying the SSPB brake, OEMs can now maximize reach while specifying this highly reliable solution from a trusted source.

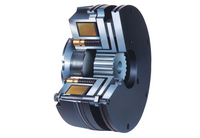

Warner electric clutches and brakes

Complete packaged clutch brake combinations for general purpose use or for integration with (electric) motor and load to form a complete assembly.

- Electromagnetic or spring applied

- Pre-assembled in our workshop

- Standard torque range : 7,5 to 970 Nm

Individual clutches and brakes

- Electromagnetic, hydraulic, pneumatic or mechanically operated

- Finished bores and keyway’s machined in our workshop

- Standard torque range : 1,7 to 81900 Nm

Spring applied electro release holding brakes

- Pre-assembled in our workshop

- Single and dual friction disc versions

- Standard torque range : 5 to 25600 Nm

Compact and economic power supplies for all electric models

- Normal excitation for standard operation and over-excitation for rapid cycling applications

- Standard output voltages 24, 103.5 and 207 VDC

Warner electric clutches & brakes operate with DC or rectified AC voltage. The standard voltages are 24, 103.5 and 207 Volts. Warner Electric offers power supplies to convert the AC voltage and to maintain a DC switching ensuring short response times. All power supplies meet the applicable CE standards. Switching is possible on the AC or the DC side, however, switching on the AC side is 5 to 6 times slower then DC side switching. Certain electro release devices apply a bi-voltage; the high voltage is used during the actual engagement, while the low voltage is used to hold the armature in position. Typical voltage combinations are 103.5/48 or 207/103.5 VDC.