Duplomatic

Hydraulic components:

The flow control:

- switchgear

- Check valves

- Hydraulic locks

- Braking valves

- Selection valves

- Logical gates

The flow control:

- Butterfly valves

- Butterfly valves with the stabilization of the pressure gradient

- Sequence valves

Pressure control:

- Insurance and bypass valves

- Reducing valves

- Sequence valves

- Pressure relief valves, the performance of batteries

Accessories:

- Electronic control units

In version:

- Single-stage (direct control) and two-stage (indirect management)

- Slide valve or gabled

- Manual, hydraulic, pneumatic, electric jump and electric proportional control

- Built on board (CETOP) or modular

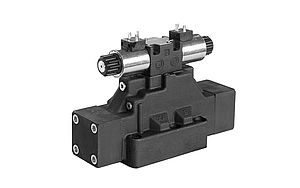

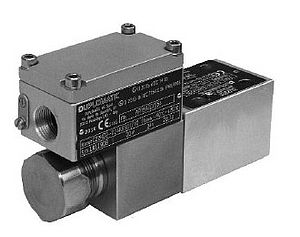

DUPLOMATIC – DSP5 two-stage brightness distributor 10

DSP5 are two-stage switchboards with electro-hydraulic clearance control 10 for mounting on a board:

- in the standard version with the assembly diagram CETOP 4.2-4 P05-350

- in a special version DSP5R with assembly pattern ISO 4401-05-05-0-05 (CETOP 4.2-4 R05-350)

Version DSC5 (DSC5R) is a switchgear with hydraulic control.

These distributors are designed for flow rates up to 150 l/min with a maximum pressure of 350 bar.

They are also available in a high-pressure version up to a pressure of 420 bar.

These switchboards replace the original E4P4 switchboards.

They are available in the following versions:

- with a two-position or three-position slider

- electric or hydraulic control

- electrical – versions with different values of control voltage and different types of connectors and versions of manual emergency control

- external or internal supply / waste of control pressure

DUPLOMATIC DXJ5

Proportional servo valve with feedback and integrated electronics

The DXJ5 is a board-mounted four-way proportional servo valve with a connection pattern according to ISO 4401-05.

This servo valve is controlled by a linear motor, thanks to which it has excellent dynamic properties independent of the pressure in the hydraulic system.

The slider position control is in a closed control loop with a linear position transducer (LVDT) - this achieves high accuracy and repeatability of the setting. The servo valve has integrated electronics based on SMD technology, which does not require any adjustment.

The DXJ5 is suitable for position, velocity and pressure control applications in a closed control loop.

In case of loss of power or a zero reference signal, the slider automatically resets to the center position. In this position, the valve has minimal leakage depending on the operating pressure.

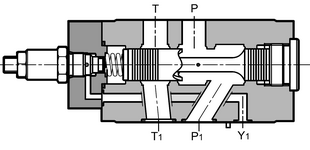

DUPLOMATIC – ZD3 – proportional reducing valve NG06

ZDE3 are 06 single-stage proportional pressure reducing valves for plate mounting with mounting pattern according to ISO 4401-03-02-0-05.

These valves are used to reduce and proportionally control the pressure in the secondary circuit branch.

ZD3 can be controlled directly - by a current control unit, or by means of an electronic control unit, which allows full use of the properties of the valve.

They are available in the standard version (normal environment) ZD3 or in the version for an environment with a risk of explosion ZD3K.

Technical parameters:

- inlet pressure (port P) 30...100 bar

- maximum pressure on waste (port T) 30 bar

- reduced pressure (port A or B) max. 23 bar

- maximum flow 15 l/min

- power supply 12VDC or 24VDC current PWM signal

- ZD3K - conversion to an environment with a risk of explosion in accordance with ATEX, IECEx, INMETRO, PESO

- low-temperature version up to -40 °C (for ZD3K)

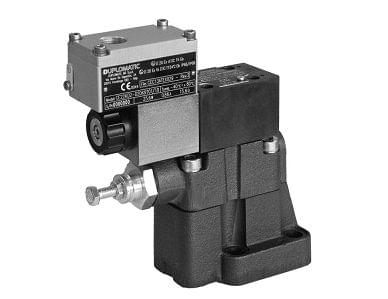

DUPLOMATIC–DSP8 two-stage brightness distributor 25

DSP8 are two-stage switchboards with electro-hydraulic control for mounting on a board with mounting pattern ISO 4401-08 (diameter Ø25).

Version DSC8 is a switchboard with hydraulic control.

These distributors are designed for flows up to 600 l/mins with a maximum pressure of 350 bar - there is also a high-pressure version up to a pressure of 420 bar.

They are available in the following versions:

- with a two-position or three-position slider

- electric or hydraulic control

- electrical – versions with different values of control voltage and different types of connectors and versions of manual emergency control

- external or internal supply / waste of control pressure

DUPLOMATIC–DSPE two-stage proportional switchgear

DSPEs are two-stage electrical proportional distributors without feedback with a mounting pattern in accordance with the ISO 4401 standard. DSPE proportional distributors are designed for continuous flow and direction control.

They are produced in five sizes, for a flow rate of up to 1,000 liters per minute:

- DSPE5 – lightness 10mm

- DSPE7 – lightness 16 mm

- DSPE8 – lightness 25 mm

- DSPE10 – lightness 32 mm

- DSPE11 – 32 mm light with enlarged connections

and in various versions:

- two-position or three-position

- closed or open center

- with regenerative function

- an internal or external source of control pressure

- internal or external control pressure waste

- with a supply voltage of 12 VDC or 24 VDC with PWM

- different types of manual emergency control

- with increased protection against corrosion

DUPLOMATIC–DSP1 two-stage clearance distributors 32

DSP10 and DSP11 are two-stage switchgears with electro-hydraulic control.

DSC10 and DSC11 are switchgears with hydraulic control.

DSP10 (DSC10) are intended for mounting on a board with mounting pattern ISO 4401-10 (clearance Ø32).

DSP11 (DSC11) are intended for mounting on a board with mounting pattern ISO 4401-10 with enlarged connections (diameter Ø48).

These distributors are intended for applications with a maximum pressure of 350 bar and for flows up to 1600 l/min.

They are available in the following versions:

- two-position or three-position

- electric or hydraulic control

- electrical – versions with different values of control voltage and different types of connectors and versions of manual emergency control

- control pressure supply/exhaust can be external or internal

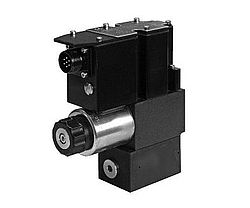

DUPLOMATIC DSE5G 4/3 proportional switchboard with integrated electronics

- DSE5G is a 4-way, 3-position resp. 2-position proportional switchboard without feedback with mounting surface according to ISO4401-05.

- It is designed to control the position or speed of hydraulic motors.

- The proportional switchboard has integrated control electronics

- Standard control electronics (G) with current (4… 20 mA) or voltage (± 10 VDC) control signal.

- Control electronics in compact design (GL) with current (4… 20 mA) or voltage (± 10 VDC), IO-Link or CAN Open control signal.

- Electronics with Fieldbus communication (GH) are also available in the following versions:

- EtherCAT

- Ethernet / IP

- Profinet

- PowerLink

Parameters:

- max. working pressure 320 bar (140 bar in branch T)

- flow up to 60 l / min

- version 4/3 or 4/2

- supply voltage 24 VDC

DAIKIN WON DUPLOMATIC MS S.P.A, ITALIAN MANUFACTURER OF COMPLEX HYDRAULIC EQUIPMENT

DaikinIndustries, Ltd. recently entered into a share purchase agreement with Duplomatic MS S.p.A ('Duplomatic'), an Italian manufacturer of hydraulic equipment. The acquisition price is 220 million euros (27.5 billion yen at an exchange rate of 1 euro = 125 yen). The acquisition is scheduled for completion in June 2022, when Daikin is expected to acquire all shares from AlcedoSgrS.p.A., An Italian private equity firm, and Duplomatic's management, after completing all necessary acquisitions.

Duplomatic is a manufacturer of hydraulic equipment that specializes in products such as hydraulic valves, pumps and cylinders, and has developed business in a wide range of areas, focusing on areas including industrial machinery and mobile construction equipment.

With a history of more than 70 years since its founding, Duplomatic has production bases in Italy, the United Kingdom, Germany, the United States and other countries. It boasts an extensive product line and robust engineering capabilities and has a strong business base in Europe that provides optimal engineering designs and hydraulic systems to meet the different needs of local customers.

For DaikinIndustries, its hydraulics division is one of the founding business areas for which the company has been in business for more than 90 years. In 2000, Daikin launched engine-driven inverter technology in the field of air conditioning with hydraulic power units with advanced energy-saving performance that overtook the entire industry. Since then, it has expanded its business with a focus on expanding a series of energy-efficient hydraulic equipment and developing applications.

In its FUSION 25 Strategic Management Plan, which focuses on fiscal 2025, Daikin has set a global business expansion for its hydraulics business as part of its core strategy. As carbon neutrality initiatives are on the rise, the trend towards energy savings for production facilities is advancing in Europe, one of the world's leading markets for industrial hydraulic equipment, and Daikin sees this development as an opportunity to expand its business.

Through this acquisition, Daikin intends to achieve energy savings in industrial equipment in Europe by integrating Duplomatic's business base with its own environmental technology specialization in order to reduce the burden on the environment and contribute to a sustainable society.

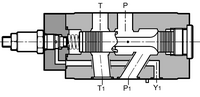

Reducing valve indirectly controlled PZM5 - modular design

PZM5 is a modular, indirectly controlled pressure reducing valve size CETOP05 with a mounting pattern according to ISO 4401-05. Used to reduce pressure in hydraulic circuits. The two-stage design ensures high stability of the regulated pressure even at variable flow through the valve. PZM5 is available in three pressure control ranges up to 350 bar. It can be supplied with a hexagon socket set screw or a rotating handle.

Features:

- Indirectly controlled pressure reducing valve in modular design.

- size CETOP05 with mounting pattern according to ISO 4401-05.

- version with pressure reduction in branches A and B, or only in branch A or in branch B.

- maximum working pressure 350 bar

- reduced pressure in three ranges from 8 to 280 bar

- maximum flow in the reduced branch 80 l / min

Proportional safety valve PLKE08

The PLKE08 valve is a single-stage proportional safety valve, cartridge type. This valve can be used in customer blocks or panels with chamber type SAE 08 (3 / 4-16 UNF-2B).

The valve is suitable as a control stage or for remote pressure control in two-stage safety, relief or reduction valves.

The valve design has a mechanical maximum pressure limitation to achieve a higher degree of safety in the hydraulic systems.

The valve can be 12VDC or 24VDC with current control with PWM modulation.

Features:

- proportional directly controlled valve - this design ensures a short reaction time of the valve. And also resistance to possible impurities in the hydraulic circuit.

- the seat construction ensures complete tightness of the valve. This allows use in applications where complete tightness is required (eg load holding systems).

- there are four pressure ranges available, from 80 bar to 350 bar

- maximum flow up to 2 l / min and max. pressure up to 400 bar

- 12 or 24VDC design - need for PWM modulation, which achieves very low hysteresis and high repeatability of controlled pressure

- without voltage, the valve is relieved - minimum pressure

- possibility of manual emergency control

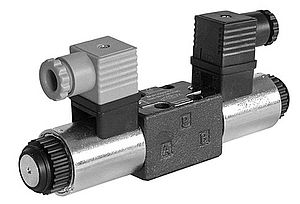

DSE2 - proportional switchboard CETOP 02

DSE2 is a proportional four-way switchboard, directly controlled with a mounting pattern according to ISO4401-02. It is designed to control the direction and size of flow in hydraulic circuits. The flow control is proportional to the control current to the manifold coil.

The valve includes a manual emergency control. This allows the hydraulic motor to be operated in the event of a power failure or valve failure.

Features:

- maximum working pressure 350 bar in branch P and max. 250 bar in branch T

- Available with three flow ranges

- various slider designs - two-position, three-position, closed center, Y-center, ...

- 12VDC or 24VDC design

- low hysteresis when using PWM control current modulation

- manual emergency control

Proportional three-way pressure reducing valve PZME3

PZME3 is a proportional, indirectly controlled, three-way pressure reducing valve of modular design. The connection pattern is CETOP 03 (according to ISO 4401-03-02-0-05).

Reducing valves are used in hydraulic circuits where, for some reason, it is necessary to reduce the working pressure or maintain a constant working pressure.

Features:

- Indirectly controlled valve - this design ensures low pressure drop at higher flow rates.

- three-way design - ensures pressure reduction from the source to the required pressure level (reduction function) and also limits the working pressure in the controlled branch of the hydraulic circuit (safety function), if necessary.

- proportional control - provides the possibility of remote control of the required pressure.

- pressure ranges up to 230 bar available

- maximum flow in the controlled branch up to 30 l / min and max. pressure up to 320 bar.

- 12VDC or 24VDC design

- The pressure is controlled by PWM modulation of the supply voltage.

Safety valve directly controlled by PLK08

The PLK08 valve is a directly controlled seat safety valve, cartridge type. This valve can be used in customer blocks or panels with chamber type SAE 08 (3 / 4-16 UNF-2B).

This valve controls the maximum pressure or limits pressure peaks in the hydraulic circuits. It can also serve as a control stage for indirectly controlled valves.

Features:

- directly controlled valve - this construction ensures a short reaction time of the valve. And also resistance to possible impurities in the hydraulic circuit.

- the seat construction ensures complete tightness of the valve. This allows use in applications where complete tightness is required (eg load holding systems).

- six pressure ranges are available, from 35 bar to 350 bar

- maximum flow up to 3 l / min and max. pressure up to 400 bar.

- the pressure is adjustable with an adjusting screw with an internal hexagon or a rotating handle.

Safety valve indirectly controlled by PRM7

Duplomatic has introduced a new safety valve indirectly controlled by PRM7 DN16 in a modular design. The mounting pattern is in accordance with ISO 4401-07.

Features:

- indirectly controlled valve (two-stage) - this construction ensures high stability of controlled pressure in a wide range of flows, all at low pressure loss

- quick and easy installation under all ISO 4401-07 modular valves using connecting rods or screws. This makes it possible to create a compact modular block.

- 5 possible pressure ranges - from 6 to 350 bar

- max. working pressure 350 bar

- flow up to 300 l / min

- adjustment - internal hexagon or rotating handle

Reducing valve indirectly controlled by PZM7

Duplomatic has introduced a new reducing valve indirectly controlled by PZM7 DN16 in a modular design. The mounting pattern is in accordance with ISO 4401-07.

Features:

- indirectly controlled valve (two-stage) - this construction ensures high stability of reduced pressure in a wide range of flows, all at low pressure loss

- quick and easy installation under all ISO 4401-07 modular valves using connecting rods or screws. This makes it possible to create a compact modular block.

- 5 possible reduced pressure ranges - from 6 to 300 bar max. working pressure 350 bar

- flow up to 300 l / min

Throttle valve with bypass QTM7

Duplomatic has introduced a new throttle valve with bypass QTM7 diameter DN16 in a modular design. The mounting pattern is in accordance with ISO 4401-07.

- It can be quickly mounted under all ISO 4401-07 modular valves without the use of pipes, using suitable connecting rods or screws, thus creating compact modular groups.

- Available in two versions: for meter flow control in one (port A) or in both drive ports, independently.

- Supplied with hexagon socket set screw and lock nut. Turn counterclockwise to increase the flow.

Features:

- quick and easy installation under all ISO 4401-07 modular valves using connecting rods or screws. This creates compact modular blocks. No additional hydraulic connections via pipes or hoses are required.

- flow regulation is realized on the waste from the appliance (meter out)

- These valves are available in two versions

- for flow control in branch A

- for flow control in both branches A and B.

- working pressure range up to 350 bar

- flow up to 300 l / min

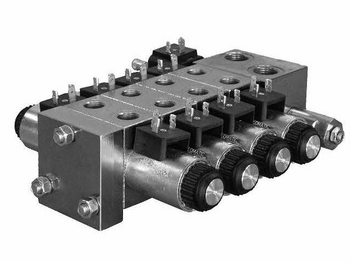

DUPLOMATIC M * F3 Modular enclosures DN06

M * F3 are shut-off valves, electrically or hydraulically operated, with or without monitoring the slider position. These cabinets are of modular design of DN06 with mounting pattern according to ISO 4401-03.

These switchboards are usually installed in the control branch of two-stage proportional switchboards where they have a safety function. In the event of a control signal failure or power supply to the proportional directional control stage, these shut-off valves ensure the safe positions of the proportional directional control switch.

They are designed with floating, closed or cross connection of the slider in the basic position - state without tension.

The slider position monitoring version does not have a manual emergency control and cannot be disassembled because of its possible use in equipment that is subject to special safety requirements.

Monitoring of the slider position can be done - either monitoring of working position (slider adjusted) or basic position.

Proportional valve series with integrated electronics with new interfaces

Duplomatic has introduced a complete range of proportional valves with integrated electronics and various interface types:

- Standard control electronics with current (4… 20 mA) or control signal (0… 10VDC / ± 10 VDC).

- Control electronics in compact design with current (4… 20 mA) or voltage (0… 10VDC / ± 10 VDC), IO-Link or CAN Open control signal.

- Fieldbus control electronics version:

- CAN Open

- PROFIBUS DP

- EtherCAT

- Ethernet / IP

- Profinet

- PowerLink

This valve series includes:

PDE3G proportional safety valve

https://www.duplomatic.com//assets/SchedeTecniche/GB/81221.pdf

PDE3J proportional pressure relief valve with pressure feedback

https://www.duplomatic.com//assets/SchedeTecniche/GB/81231.pdf

Proportional safety valve, two-stage PRE3G

https://www.duplomatic.com//assets/SchedeTecniche/GB/81251.pdf

Proportional Distribution Box DN06 DSE3G

https://www.duplomatic.com//assets/SchedeTecniche/GB/83220.pdf

DN10-32 DDPE * J Proportional Switchgear

https://www.duplomatic.com//assets/SchedeTecniche/GB/83350.pdf

Proportional reducing valve ZDE3G

https://www.duplomatic.com//assets/SchedeTecniche/GB/81520.pdf

DUPLOMATIC DSE3G

4/3 proportional switchgear with integrated electronics

DSE3G is a 4-way, 3-position or 3-way 2-position proportional switchgear with mounting surface according to ISO4401-03.

It is designed to control the position or speed of hydraulic motors.

The proportional switchgear has integrated control electronics

Standard control electronics (G) with current (4… 20 mA) or voltage (± 10 VDC) control signal.

Control electronics in compact design (GL) with current (4… 20 mA) or voltage (± 10 VDC), IO-Link or CAN Open control signal.

Also available is Fieldbus electronics in:

- CAN Open

- PROFIBUS DP

- EtherCAT

- Ethernet / IP

- Profinet

- PowerLink

DT3K * 3/2 explosion-proof seated valve

- DT3K * is a 3/2 directly controlled seated electric switchgear and mounting surface according to ISO 4401-03.

- is normally open (NO) or normally closed (NC) in the version with three connections.

- these switchboards are used in hydraulic circuits where high tightness (100% tightness) is required.

- they are used at a flow rate of 25 l / min and up to 350 bar.

- these switchboards are in compliance with ATEX, IECEx and INMETRO standards for use in hazardous areas in production plants as well as in mining areas.

- Corrosion resistance is also available.

QDE3K * Proportional throttle valve with non-explosive stabilization

QDE3K * are throttle valves with two-way or three-way design.

- have a mounting surface according to ISO 6263-03 with a two-way or three-way construction depending on the use of port P.

- they are used for proportional flow control up to 40 l / min at a pressure up to 350 bar.

- these valves are in accordance with ATEX, IECEx and INMETRO standards for use in potentially explosive atmospheres in production facilities as well as in mines.

- The valves can be controlled directly by a power source or an electronic control unit.

- Also available for low temperatures (up to -40 ° C) as well as increased resistance to corrosion.

DS2 - On / Off distributor NG04

- On / Off directly controlled (single stage) hydraulic switchboards with electric control and plate mounting according to ISO4401

- Compact design with reduced coil dimensions suitable for mini-aggregates, mobile and agricultural applications

- the switchgear body is made of high-strength cast iron

- internal channels with a large cross-section to minimize pressure losses.

- The distributor is supplied in a four-way version with two, three working positions and sliders with different interconnections

- switchboards are available with a zinc-nickel finish that resists an aggressive work environment

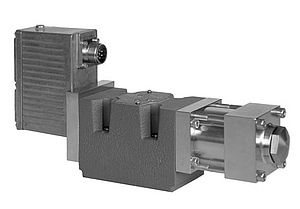

DUPLOMATIC DXE5J

Rapid feedback, feedback, and integrated electronics

- The DXE5J servo valve is a 4-position (3 working positions + safe position) where the slider moves in the housing. The servo valve operates with a proportional high-speed coil, which achieves high operating parameters and no control pressure is required. The position of the slide is monitored by a linear position transmitter (LVDT) in a closed control loop, which guarantees high steering precision and high repeatability of positioning.

- The servo valve is available in 2 different flow sizes of up to 100 l / min, with a zero cover slide.

- Servoventil is equipped with integrated electronics based on SMD technology, which provides standard control and simplifies electrical cabling. The unit does not require any setting other than electronic zero positioning.

- The servo valve is suitable for applications to accurately control the position, speed or pressure in a closed loop. In the event of a power failure or a loss of the pilot signal, the slider is automatically moved to a safe position.

PDE3K and PRE * K Proportional release valve in explosion-proof design

- PDE3K and PRE * K are releasable valves with proportional control

- PDE3K are single-stage valves designed for proportional pressure control up to 350 bar and flow rate up to 2 l / min

- PRE3K are two-stage valves designed for proportional pressure control up to 350 bar and flow rate up to 40 l / min

- PRE10K are two-stage valves designed for proportional pressure control up to 350 bar and flow rate up to 200 l / min

- PRE25K are two-stage valves designed for proportional pressure control up to 350 bar and flow rate up to 400 l / min

- PRE32K are two-stage valves designed for proportional pressure control up to 350 bar and flow rate up to 500 l / min

- these valves comply with ATEX, IECEx and INMETRO standards for use in potentially explosive atmospheres

- The valves can be controlled directly by a power source or an electronic control unit

- also available for low temperatures (up to -40 ° C) as well as increased resistance to corrosion

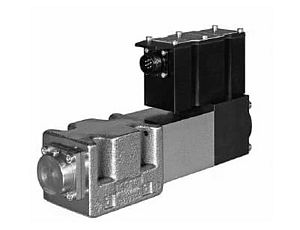

BD STACKABLE DIRECTIONAL CONTROL VALVE

- BDL, BDM and BDS are stacked valve assemblies, very well-rounded thanks to their modular design.

- Elements have been designed to be assembled in parallel connection, mounting up to 10 stackable valves. The same elements allow to create series circuits by inserting plugs in order to divert the oil path.

- Elements specifically designed for BD*2 series circuits complete the BD* range.

- BD* assemblies are suitable for compact applications in the mobile and in mini-power pack industries.

- Directional valve elements are available in two thicknesses, with working ports 3/8” BSP, 1/2” BSP, SAE–06 and SAE–08 threaded

DXPE*J - Directional control valve, pilot operated, with OBE and feedback

- DXPE*J are directional control valves operated by a servo-proportional pilot, with mounting surface compliant with ISO 4401 standards.

- The spool position is controlled by a linear transducer LVDT in closed loop, which ensures high precision and repeatability. In the event of switch-off or inactive electronics the main spool is set to a fail-safe position by springs.

- The valve is featured by integral electronic based on SMD technology which ensures standard regulations and simplifies the electric wiring. The unit does not require any adjustment.

- The valve is easy to install. The driver directly manages digital settings. In the event of special applications, you can customize the settings using the optional kit.

DXE3J - High response servo-proportional valve with feedback and integrated electronics

85120

- The DXE3J valve is a four-way (3 + fail-safe position) servo-proportional valve where the spool moves inside a sleeve. It is operated by a proportional solenoid highly dynamic, which achieves high performance and not requires pilot pressure. The spool position is controlled by a linear transducer (LVDT) in closed loop which ensures high precision and repeatability.

- It is available in four different flow ranges up to 40 l/min, with spools with zero overlap.

- The valve is featured by integral electronic based on SMD technology which ensures standard regulations and simplifies the electric wiring. The unit does not require any adjustment other than the possible electronic regulation of the zero.

- Suitable for control applications with closed loop of position, velocity and pressure. With a power down or without the enable input, the spool moves automatically at fail-safe position.

Peter Lauko

Tel.: +421 37 7777 955

Mobile: +421 903 282 644

Fax: +421 37 7777 967

Email:lp@bibus.sk

Jaroslav Tvrdoň

Tel.: +421 37 7777 954

Mobile: +421 914 336 525

Fax: +421 37 7777 967

Email: tvr@bibus.sk

Vladimír Begáň

Tel.: +421 37 7777 954

Mobile: +421 914 336 527

Fax: +421 37 7777 967

Email:vbe@bibus.sk