Piab's conveyors for the chemical fertiliser industry

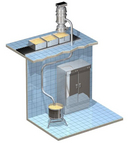

The production of #fertilizers and chemical-mineral fertilizers, in the various process steps, requires the handling of powders or granules that are hazardous to human health due to their potential toxicity. This is e.g. the case when conveying urea (pictured) from a big bag to a packaging machine. It is therefore essential to minimize the exposure of operators to these materials. The closed design of our conveyors, equipped with state-of-the-art ULPA filters, prevents product losses and avoids contamination with the surrounding environment, guaranteeing maximum worker safety.

In addition, Piab has developed a speed control system that optimizes conveying efficiency without damaging the product. Our ATEX-certified solutions therefore reduce waste and increase productivity.

Vacuum conveyors Piab

Vacuum is used with many advantages to transport dry, loose materials through a hose or pipe. PIAB vacuum systems consist of strong, high-quality components. They offer solutions to help customers increase productivity.

The production of food, pharmaceuticals and chemical products requires the highest possible level of safety in terms of hygiene and functionality. The new series of PIAB vacuum conveyors was developed in response to the requirements of work safety and hygiene in the food, pharmaceutical and chemical industries.

Advantages of PIAB vacuum transport

Perfect for powders and granules

Industries that produce food, pharmaceuticals and chemical products have discovered the advantages of vacuum transport. PIAB, which has been developing conveyors for 25 years, has a leading position in this industry. We provide solutions for your transport problems!

Friendly to your health and the environment

Different powders require different vacuum levels for transport. With PIAB conveyors, you simply set the energy consumption exactly according to the prevailing conditions.

From 0 to 20 meters in 1 second

Time is money. Vacuum technology offers you the transport of powders at express speed. Systems up to 30 m long (sum of horizontal and vertical routes).

15 tons per hour

During tests, up to 15 tons per hour were measured over short distances under favorable conditions.

Easy installation anywhere

Our systems are easily adapted to the conditions in your operation thanks to the small number of components, small dimensions and low weight. The modular system facilitates installation. The basic unit is supplied "turnkey", just plug in the compressed air!

Long-lasting material

Conveyors are made of stainless, highly polished steel (ASTM 316L). The material is resistant to acids and has very "strong" properties. We offer a 5-year warranty (except for the filter and consumables).

Reliable with easy maintenance

Our systems require a minimum of maintenance. They are easy to clean, filter cleaning is automatic. Both work and control are fully pneumatic in the standard version.

Functional safety

The design of the PIAB vacuum conveyor and vacuum pumps offer the highest possible functional safety.

Hygiene

Conveyors are primarily adapted to the food and pharmaceutical industries.

A safer working environment in the food and pharmaceutical industry

The WIP (Wet-In-Place) function has been added to the popular piFLOW®p vacuum conveyors. WIP spray nozzles are now available for inclusion or retrofitting in new and existing piFLOW®p conveying systems.

The water sprayed by the WIP nozzles soaks any dust from food or pharmaceutical materials left in the conveyors and prevents them from escaping into the air where they can be inhaled by the processing worker during maintenance or cleaning. By wetting down potentially harmful residual material before opening the equipment for cleaning, spray nozzles ensure that any such dust remains Wet-In-Place until it can be safely removed.

For maximum performance and to ensure the fastest possible capture of the largest amount of material, up to three WIP modules can be mounted on each conveyor. The configurable design of the piFLOW®p conveyor also allows easy retrofitting of WIP units. The piFLOW®p conveyor for powder and bulk materials is designed to perfectly meet the strict requirements for operational safety and hygiene in the food and pharmaceutical industries.

A safer working environment in the food and pharmaceutical industries

The WIP (Wet-In-Place) function has been added to the popular vacuum conveyors piFLOW®p. WIP spraying nozzles are now available for inclusion or retrofitting to new and existing piFLOW®p conveying systems.

Water sprayed with WIP nozzles dries any dust from food or pharmaceutical materials left in conveyors and prevents them from escaping into the air, where they can inhalate the worker during the maintenance or cleaning process. By brushing the potentially harmful material residue before opening the cleaning device, the spray nozzles ensure that each such dust remains Wet-In-Place until it can be safely removed.

For maximum performance and to ensure the fastest capture of as many material as possible, it is possible to mount up to three WIP modules on each conveyor. The configurable construction of the piFLOW®p conveyor also allows simple additional WIP units. The piFLOW®p conveyor for powder and loose materials is designed to perfectly meet stringent operational and hygiene requirements in the food and pharmaceutical industry.

Evolving automation

Handling of bulk material for nutraceuticals using Piab conveyors.

Productivity with minimal footprint.

Nutraceuticals, such as dietary supplements and superfoods, have similar requirements to the food and pharmaceutical industries. During their production process, it is essential to prevent cross-contamination and the formation of powder.

Our piFLOW® conveyors for the automated handling of bulk material such as plant extracts, fiber, herbs, excipients, antioxidants, calcium, magnesium, potassium, vitamins, etc. meet these requirements perfectly thanks to their closed design and easy cleaning.

They meet the high standards of hygiene and safety in the industry, have an ultra-compact footprint and ensure gentle transport, quick product changes and high productivity. Therefore, they are also ideal for handling capsules and tablets in packaging machines.

At Piab, we are also able to supply automatic lines with customized designs thanks to our extensive experience in vacuum conveying. In fact, our conveyors have been used for over 40 years in the food, chemical and pharmaceutical industries.

Greater efficiency with the new piFLOW® BVO conveyor

Piab has integrated a new batch volume optimization (BVO) function into its piFLOW® line of conveyors. BVO ensures faster, more efficient and safer handling of bulk material through batch optimization using a level sensor, preventing unexpected downtime