Circulation lubrication

Circulation lubrication requires a constant oil flow to a given lubrication point. Oil flows back through the return ducts to the supply tank and from here it is again distributed to the lubrication point.

Pumping village named is equipped with cooling, heating or other device to ensure optimal temperature of the lubricating medium. When circulation lubrication bearing member to remain constantly filled with oil.

Rapid oil flow efficiently removes the heat generated and thus the user provides the possibility of higher speeds and performance.

Catalogues

http://www.dropsa.com/components-catalogue.html

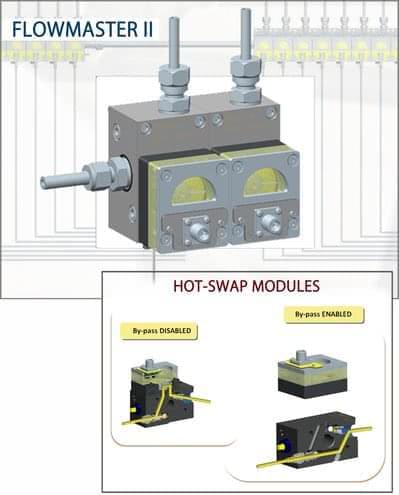

FLOWMASTER II

Increases the reliability of your lubrication system!

The key to an efficient lubrication system is the ability to be able to regulate and dispense the oil flow in a precise, consistent and repetitive way.In order to achieve this goal, DropsA has developed a specific technology: the FLOWMASTER II, a device with remote diagnostics capable of ensuring maximum efficiency and control over recirculating oil lubrication systems.

FLOWMASTER II is equipped with the new "HOT-SWAP MODULES" SYSTEM", the system that allows the by-pass to be enabled in order to replace the module easily without having to interrupt lubrication.

Functional principle: The liquid flow inside the metering module moves a “satellite” that describes fixed orbits. Each orbit is detected by an inductive sensor that transmits the signal to a monitoring device. The operator can read the number of litres of liquid dispensed per minute or the number of revolutions per minute directly on the FACT Controller display or on the monitor of a personal computer.

The FOLWMASTER II is most suited for application in the energy and paper mill sector because it favours an increase in work speed and performance.

Viliam Moravec

Tel.: +421 37 7777 953

Mobile: +421 903 720 733

Fax: +421 37 7777 968

Email:vmo@bibus.sk