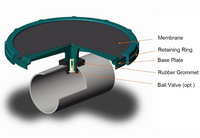

Disc Diffuser

The disc diffuser series combines cost effective design, low installation costs, reliability and performance in intermittent and continuous aeration processes.

- Precision die cut openings for high oxygen tranfer efficiency and performance: The operating pressure can be adjusted to customer or system specification by using different slit patterns varying the number and length of the slits and the spacing between the slits

- Active diameter between 184 mm and 295 mm

- Different standard and special membrane materials specially engineered for a wide spectrum of applications:

- EPDM: municipal wastewater

- Low plasticizer EPDM: animal processing, food processing, beverage production

- Silicone: pulp and paper industry, petrochemical and refining processes

All membrane materials can be equipped with an anti-fouling surface based on nano technology to prevent build up of solids and biological encrustations.

- Glass fiber reinforced polypropylene body plate and ring for maximum chemical, temperature and UV resistance

- Different orifice sizes to adapt various air flows

- Check valve integrated into body plate, optional ball valve available

- Easy mounting on 3-inch and 4-inch IPS pipe as well as 90-mm and 110-mm diameter metric pipe of any thermoplastic material (PVC, CPVC, PP, ABS etc).

- EPDM rubber grommet

- Glue-on PVC saddle (for PVC only)

- Low maintenance requirements

- Standard units in stock for immediate shipment.

Tube diffuser

The Jaeger TD™ tube diffuser series combines cost effective design, low installation costs, reliability and performance in intermittent and continuous aeration processes.

- Precision die cut openings for high oxygen transfer efficiency and performance: The operating pressure (DWP) can be adjusted to the system specification by using different slit patterns varying number and length of slits and the spacing between the slits

- Active length from 200 – 1200 mm with standard length of 500 mm, 750 mm, and 1000 mm

- Mounting onto round and square tube laterals.

- Different membrane materials (can be equipped with an anti-fouling surface based on nano technology):

- EPDM: municipal wastewater

- Low plasticizer EPDM: animal processing, food processing, beverage production

- Silicone: paper and petrochemical industry

- Polyurethane: petrochemical industry

JetFlex® CBD for Efficient Mixing

For special applications, coarse bubble diffusers are also available from our product portfolio, either in a disc design or as a stainless steel tube type. Installed in a sand trap or as a post-aeration, they offer the possibility to put through large amount of air. Thus, the water is best circulated or a certain oxygen concentration in the effluent may be maintained. In addition, these diffusers are applied in activated sludge tanks in order to induce vertical flow so to prevent sludge settlement on the tank floor.

JetFlex coarse bubble diffusers also offer numerous other product specific advantages:

JetFlex® CBD 105 (disc diffuser):

- Diameter of 105 mm

- Silicone membrane and glass fiber reinforced plastics for maximum chemical and thermal resistance

- Non-return valve (optionally)

Jetflex® SS-CBD (tube diffuser):

- Two standard lengths of 335 mm and 630 mm available

- Material in stainless steel and so applicable in a high corrosive waste water

- Even at high temperature a reliable aeration system