HIT® - Hybrid Integrated Tank

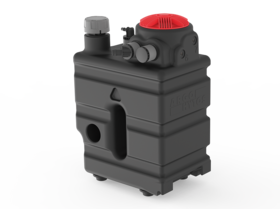

The “hybrid tank“ intelligently combines the two manufacturing technologies rotational molding and injection molding. The unique combination of innovative production processes with a modular kit makes the “hybrid tank“ economically interesting even for small quantities.

Function

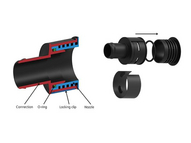

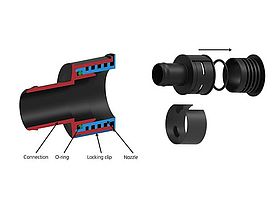

The hybrid tank is a ready-to-install complete module. All required tank functions are already integrated. Since the filter housing is part of the tank, there are no sealing points and therefore no risk of leakage. The tank geometry can be adapted as required to the installation situation. Numerous components such as filter cover, “Quick-Connect fittings“, etc. come from an existing modular system and do not cause any tool costs to the customer. 100% replacement filter element business is ensured by a special copy protection. The high thermal strength of the Polyamide material used allows the tank to be used even at higher operating temperatures. Quick-Connect fittings allow fault-free and tool-free hose mounting on the tank and can also be dismantled at any time.

Technical Data:

| Tank volume Vmax | up to 150l |

|---|---|

| Temperature Tmax | -30°C … +100 °C short-term up to +120 °C |

| Fluids | mineral oil and environmentally friendly hydraulic fluids (HEES and HETG, see info sheet 00.20-EN) |

Integrated filter functions:

- Return filter 10 … 30 µm

- Return-suction filter 10 … 16 µm

- Suction strainer 140 … 280 µm

- Ventilating filter 2 µm

- Filling filter 140 … 450 µm

Advantages of the ARGO-HYTOS hybrid tank:

- Installation of a complete module in the machine

- Complex geometries can be realized

- Weight reduction

- High mechanical strength and thermal stability by using Polyamide

- There is no risk of leakage between the filter head and the tank

- Excellent corrosion resistance

- Multiple ports save hose collection manifold

- Tool-free assembly of Quick-Connect fittings

- Cost savings compared to traditional tank solutions

- Copy-protected filter elements

- Tank development “Made in Germany“

Peter Lauko

Tel.: +421 37 7777 955

Mobile: +421 903 282 644

Fax: +421 37 7777 967

Email:lp@bibus.sk

Jaroslav Tvrdoň

Tel.: +421 37 7777 954

Mobile: +421 914 336 525

Fax: +421 37 7777 967

Email: tvr@bibus.sk

Vladimír Begáň

Tel.: +421 37 7777 954

Mobile: +421 914 336 527

Fax: +421 37 7777 967

Email:vbe@bibus.sk